Flex应用专题 | 解锁蛋白质谱前处理自动化的无限潜能

Check the Details-

article · 2025Year27Moon6Day

微孔板振荡器在工作站中的应用

Read More -

article · 2025Year22Moon6Day

全自动移液工作站哪个品牌好

Read More -

article · 2025Year21Moon4Day

DNA半保留复制实验有哪些注意事项

Read More

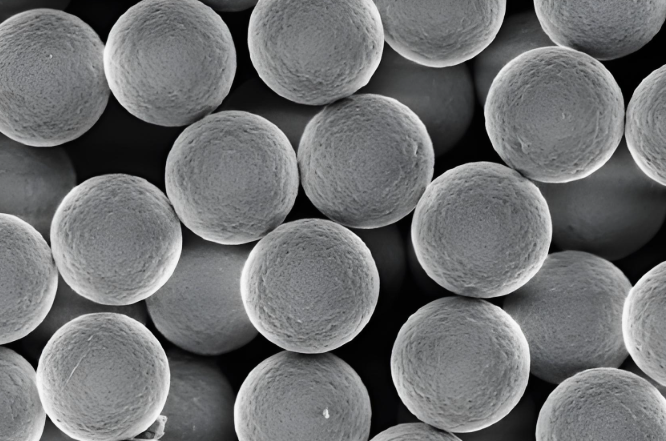

In the field of chromatography analysis, C18 packing plays a vital role as an efficient and stable separation medium. Its unique eighteen-carbon chain structure gives it a strong affinity for hydrophobic compounds, allowing the C18 packing to exhibit excellent separation effects and resolution in reversed-phase chromatography. However, the preparation process of C18 fillers is not easy. It involves complex chemical reactions, fine particle synthesis, and strict quality control.

1. Synthesis method 1. Steps: Carboxylize or anhydride the C18 chain so that it has the ability to react with silica gel or other carriers. Then, under certain conditions, this treated C18 chain is reacted with silica gel or other carriers to form C18 filler. 2. Advantages: The synthesis method can precisely control the length and bonding method of the C18 chain, thereby obtaining C18 fillers with specific properties.

2. Modification method 1. Step: Modify some common fillers, such as silica gel, polystyrene, etc., through chemical or physical methods to make their surfaces carry C18 functional groups. 2. Advantages: The modification method can use existing fillers for modification and reduce production costs. At the same time, by selecting different modification methods and conditions, the distribution and number of C18 functional groups on the surface of the filler can be controlled.

3. Modification method 1. Step: Use some fillers that are easier to prepare, such as glass beads, polyethylene chips, etc., to modify the surface with C18. This usually involves immobilizing C18 functional groups on the filler surface through chemical bonding or physical adsorption. 2. Advantages: The modification method can flexibly select different types of fillers as bases and give them C18 properties through the modification process. This method has advantages in preparing C18 fillers of special shapes and sizes.

4. Copolymerization method 1. Step: Copolymerize C18 monomer with other monomers under certain conditions to form a polymer with C18 functional group. This polymer is then used as a filler. 2. Advantages: The copolymerization method can control the structure and properties of the polymer by adjusting the monomer ratio and reaction conditions, thereby obtaining C18 fillers with specific properties. This method has advantages in preparing high molecular weight, high stability C18 fillers.

5. Specific examples (taking the preparation of C18 reversed-phase mesoporous chromatography packing as an example) 1. Acidification treatment of silica gel: Weigh a certain amount of silica gel, place it in a beaker, add concentrated hydrochloric acid and stir, leave it for a period of time, and then use deionized water. Wash repeatedly until the filtrate becomes neutral and dry under vacuum. 2. Bonding of C18 functional groups: Use compounds such as n-octadecyltrichlorosilane to react with the hydroxyl groups on the silica gel surface, so that the n-octadecyl groups are connected to the silica gel surface through silicon-oxygen bonds. 3. Performance optimization: Through process optimization, the stability of the bonded phase can be improved, thereby extending the service life of the chromatographic column.

6. Notes 1. Raw material selection: When selecting raw materials, it is necessary to ensure their purity and quality to avoid adverse effects on the performance of C18 filler. 2. Reaction conditions: During the preparation process, conditions such as reaction temperature, time and pressure need to be strictly controlled to ensure the smooth progress of the reaction and the quality of the product. 3. Post-processing: After the preparation is completed, the C18 filler needs to be post-processed, such as washing, drying and screening, to remove impurities and improve the uniformity and stability of the filler.

The preparation method of C18 filler is a multi-step process involving complex chemical reactions, fine particle synthesis and strict quality control. From the careful selection of raw materials, to the precise control of chemical reaction conditions, to the continuous optimization of particle synthesis technology, every step is crucial and together determines the final performance and quality of C18 filler.

Related reading recommendations

Automated Elisa (enzyme-linked immunosorbent assay) using Opentrons pipetting stations

Proteomics sequencing sample requirements

Application of fully automatic pipetting workstation and C18 column in HPLC

Opentrrons fully automatic pipetting workstation glue recycling process

The experienced service team and strong production support team provide customers with worry-free order services.