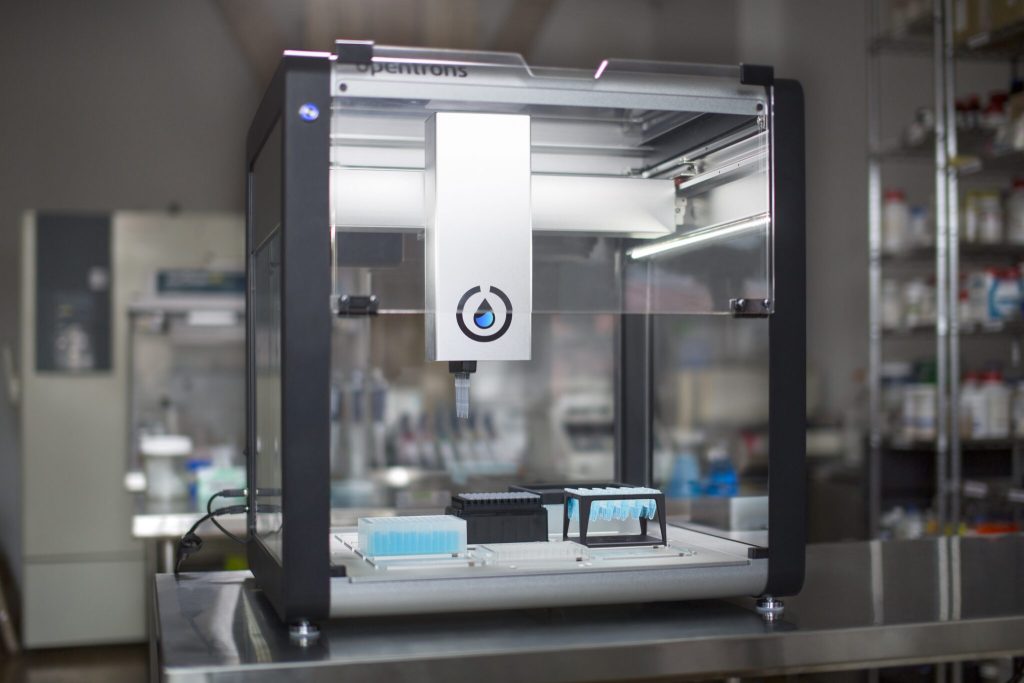

In this report, we interviewed Tom Huckvale, a senior scientist at YouSeq. He will share with you how he uses three Opentrons OT-2 automated pipetting platforms at YouSeq to develop customized gene panels and use magnetic beads to purify DNA.

YouSeq The company was founded in 2018 and is a British biotechnology company specializing in the design, development and Manufactures easy-to-use next-generation DNA sequencing (NGS) kits, panels, and reagents.

We interviewed Tom Huckvale, a senior scientist at YouSeq Company. He shared with us how YouSeq uses three Opentrons OT-2 automated transfer machines. liquid platform to develop custom genetic panels and purify DNA using magnetic beads.

Opentrons: What specific applications are your OT-2 pipetting platforms used for, and how do they fit into your workflow?

Tom Huckvale: First, they are used to extract the primers. Our NGS panel primer pairs come from the manufacturer's 96-well plates. We need to take a specific volume of primers from a specific well on a specific plate and mix them into a single tube - this way we have separate pools of primers for the NGS kit.

Sometimes we will want to mix equal volumes of each [primer] into a tube. However, as our needs grew, we began to try more and different solutions. For example, we may need to process thousands of primers and want to take different volumes of each primer from over a hundred plates and put them into a single tube for the reaction. We might not want to take everything from one board, we might just take some and then some from another board. So this is where the Opentrons pipetting platform comes into play.

The advantage of these pipetting platforms is their unique openness, which allows us to build a huge database containing all primers, all primer pairs, their performance and the quality controls that have been completed. All of these parameters can be used to create a spreadsheet that can be read by the pipetting platform. When using software from many other device manufacturers, you are often limited by the way their software handles things. Many proprietary file formats exist. But for OT-2, we only need to provide OT-2 with a very common CSV file, which contains information such as volume, hole ID, required position, etc. OT-2 can perfectly convert this information and then perform the operation.

We also have another Opentrons pipetting platform with a magnetic module in another room for DNA purification using magnetic beads. Many of our experiments involve reaction plates, and it is troublesome to manually use magnetic beads to clean the reaction plates. My colleague Daniel and I spent a week developing a magnetic bead cleaning method suitable for this pipetting platform, starting from scratch. It performed so well every time that we were able to use it for DNA cleansing of entire 96-well plates, with the OT-2 pipetting platform doing it automatically in the background.

To be honest, we could have done this manually ourselves, and since we do magnetic bead cleaning so often, we did it pretty quickly. Just in terms of the speed of magnetic bead cleaning, automation does not save much time. But it's really important to be able to set tasks and use that time to write lab reports, come up with new ideas, and do other work. You can leave these simple repetitive tasks to the pipetting platform and trust that its performance is almost the same as your manual operations.

Opentrons: I understand that you have been writing protocol scripts in Python. Why did you choose this approach instead of using Protocol Designer?

Tom: We used the Opentrons Protocol Designer application to design protocols. For users of the pipetting platform, the technical threshold for its use is very low and the operation effect is very good. But this method has some limitations, especially in magnetic bead cleaning. You cannot use the Protocol Designer application to write protocols that use magnetic modules.

So we looked into Python scripts and found that they are actually very simple to understand, especially with the help of the Opentrons API on the Opentrons website. In addition, for convenient reference, we can print the relevant information into PDF files and view them nearby at any time. This way you can find whatever you want to do in your script. While initial setup takes some time, once you're up and running, there's virtually no need for any additional input.

Opentrons: I was going to ask you why you chose Opentrons over the larger manufacturers, but I don't know if you can answer that question since the equipment already existed when you joined the company.

Tom: We are in a market where there are some very big players. These large companies often have high barriers to entry and require significant upfront investment. Since our company has limited funds, we must use our start-up capital wisely and maintain control of the company as much as possible. In order to compete with these large companies on price and product quality, we need to introduce automation technology. Automation can reduce production costs, improve production efficiency, and make our products more competitive.

Using Opentrons means we don’t need to subscribe to or learn new software in order to write protocols. In previous jobs using automation, you needed to learn new software for a specific manufacturer's specific robot. It takes several weeks to learn how to operate a specific piece of software for a particular piece of equipment, and usually once one person has learned how to use it, the piece of equipment can only be operated by that person.

We want everyone in the company to be able to write scripts for these Opentrons bots. I'd like to see ten devices sitting side by side on a lab bench and everyone in the company having at least some interaction with them at some point, even if you're just using them for fun or to try something new.

Opentrons: You mentioned that with the OT-2, you have become more competitive against larger and more experienced companies. How do you think your business would be different if you hadn't automated it?

Tom: I think if we didn't automate, we would have fewer, simpler products to offer, and probably only a handful of them. In addition, we will also have difficulty accepting new orders. Due to the open nature of the automation technology, we now have a good integration with the OT-2, which can also be put into use very quickly once a custom order is placed. Of course, we still need to thaw some reagents, but once everything is thawed, you can receive your order and start preparing experimental plates within half an hour or 20 minutes. If we do it manually, we won't be able to achieve this speed.

Additionally, manual work can lead to mistakes that can cause real trouble. We need something that performs well all the time. It may sound sad if you can free it from error, but freeing experiments from human error does make your customers happier.

Opentrons: NGS (next generation sequencing technology) essentially requires high-throughput, faster, cheaper, and more accurate. How does laboratory automation affect your experimental throughput and precision?

Tom: In terms of the research and development of these products, we can do more. If I were to design an experiment that had to be done by hand, many times I would have fewer variables to test. Using an automated laboratory pipetting platform, you can fine-tune many experiments. For example, in a primer pool, you can adjust the volume and concentration to perform individual assays, which is something you really can't do by hand. This may take you several days and break your heart.

With an automated pipetting platform... you can adjust volumes and concentrations and do individual assays that you really can't do by hand. This may take you several days and break your heart. But you can have a robot do the job in an afternoon.

This means you get a better product faster. You can optimize many of your processes. You can get answers faster. You can try more things, which means you can get the quality of product you like in fewer steps.

Overall, this made a big difference. Without a doubt I would recommend Opentrons to anyone. We have customers who want to get into NGS and they come to us to design panels for them. But we also suggested that they look into Opentrons and work on magnetic bead purification done on robots. We share the script with them and they can start running it. Opentrons offers help with this. No proprietary file formats, no security issues. You don't need a special password. You just send a text file and they can have the robot read it, no matter the distance, and the same thing happens in the lab.

Part of YouSeq's philosophy is that NGS doesn't need to be complicated at all. Many laboratories want to do NGS, but they see a lot of jargon, a lot of things really don’t make sense, it sounds really complicated, you don’t need a lot of data, you don’t need special tools... We want to say that NGS is actually not like this. Yes, it's really simple and we'll teach you how to do it. Opentrons also fit this philosophy. It's great to find a company that thinks the same way we do. Regardless, we have a lot of respect for what Opentrons does, so we want to support that as well. It just so happens that their stuff works and we love it.

In order to provide you with a better reading experience, this article has been moderately edited for length and text.