This customer interview brings you a fascinating conversation between Opentrons co-founder Will Canine and Glowee's chief scientific officer Samuel Juillot in Paris. Glowee is a French startup that uses the OT-1 PRO to create bioluminescent signs in the lab.

(In order to provide you with a concise and easy-to-understand reading experience, this interview has been edited and optimized.).

Will: Okay, I’ve seen your website, could you please share it, what is your team’s research project?

Samuel: We are working on a new way to light the cities of the future. The goal is to find a way to generate light that doesn't rely on electricity. When we look at nature, we find an ideal solution, and that's the phenomenon of bioluminescence. In nature, there are some organisms that can emit light without the support of electricity. We were inspired and wanted to apply this natural phenomenon to urban lighting.

Samuel: Sandra Rey is the founder of this project. She observed bioluminescence in nature and wondered how to exploit this property. So, the project began. Although she is a designer, she is not a biologist, so she needs to find the right person to implement the product. The company was founded in December 2014, less than two years ago. Our goal was to develop a lighting product that does not rely on electricity and requires no infrastructure. Users simply place it on the glass surface, which is as easy as applying a sticker.

Will: Awesome! It sounds like "tear and play".

Samuel: Yes.

Will: Cool! It is gradually replacing traditional neon billboards.

Samuel: Yes.

Will: It is true that there are too many neon billboards in the city, and they also consume a lot of electricity. This is awesome. When can I purchase Glowee?

Samuel: Haha, not yet.

Will: You joined the company shortly after it was founded, right? After you got your PhD?

Samuel: Yes.

Will: So what was your initial goal? What was it that you originally wanted to build? What is the milestone you hope to achieve?

Samuel: Of course, first of all we want the stable lighting to last more than 10 hours.

Will: Cool, that’s a good goal. Continues to glow steadily for 10 hours.

Samuel: And not in a liquid state. Because making liquid cultures is easy.

Will: In a oscillating bioreactor?

Samuel: Yes, oscillating, bubbling bioreactors require electricity. And we're making light that doesn't use electricity.

Will: So does this mean letting bacteria grow on agar?

Samuel: Pretty much.

Will: Pretty much?

Samuel: gelling solution.

Will: That’s right, that’s cool!

Samuel: Our CEO is a designer, so she didn’t want any gross or ugly colors. Don’t want any bad smells either.

Will: This is very important!

Samuel: So we are also committed to making the best products. We now have a luminescence time of 72 hours in the gelling medium.

Will: And then they have to replace your billboards every 72 hours?

Samuel: Currently, yes, but it is not very convenient. So our goal is to have one week of glow time by the end of the year.

Will: Great.

Samuel: You might be thinking: "Okay, but your products don't last that long compared to LED systems." I think if you use LEDs 24 hours a day, the usage of LEDs Lifespan is approximately three years. We've done a life cycle analysis, and actually in terms of CO2 consumption, if you take everything into account - the production of LEDs, the production of electricity, etc. - our lighting system has a lifespan of one week, which is more sustainable in the long run. continued. At the beginning, we emitted 3 times less carbon dioxide per unit life cycle than LED. If the lighting time is one month, the carbon dioxide emissions will be 10 times less. This is very impressive.

Will: Strongly agree.

Samuel: Of course, currently it only works in stores and only in certain markets.

Will: For now!

Samuel: Yes, for now.

Will: So, which genes did you originally use for bioluminescence?

Samuel: We initially used the lux operon from Vibrio fischeri . This is well known and was actually used in an iGEM project in Cambridge in 2010. This is the first part of the iGEM project, and they are already starting to build better light-emitting devices around this system.

Will: Is there a way to stop it from glowing during the day and then glow again at night? I'm sure you've considered all of these adjustments.

Samuel: Yes, of course. This is also the result of bio-inspired observations of plants in nature that are regulated by light. Basically, the circadian clock is an important concept and our goal is to exploit these promoters that are regulated by day and night. We're also currently working on bacteria, like E. coli, and we can control their activity with light, which is great. In fact, what I did during my PhD research was optogenetics.

Will: Open and close transactions through light?

Samuel: That’s right.

Will: That's typically used in neurobiology, right?

Samuel: Yes, it started in neurobiology, but we can now control everything with light.

Will: Okay, so it uses light to turn genetic circuits on and off?

Samuel: Actually, it starts with protein-protein interactions. You can activate a reaction or stop a reaction. So basically gene expression is simple, you change conformation and bind to DNA. But you can also imagine a system where two proteins simply interact with each other when you turn on the light.

Will: You can use light to start and stop the bioluminescence process.

Samuel: Yes.

Will: That’s cool, that’s amazing. One day, you might see your glowing object turning another object on or off with light.

Samuel: This is tricky right now. Because we also give off light, so...

Will: …Things get complicated.

Samuel: Haha, that’s right.

Will: So, tell me about your lab work. What do you usually do? A lot of bacterial culture?

Samuel: Yes, but right now we’re taking a break and we’re currently working with a company that – how do you say that in English? When you ask another company to produce something for you.

Will: Like a CRO? Or just a contractor?

Samuel: Yes. So they're responsible for producing the bacteria, because we've done four large events where we needed to produce hundreds of liters of bioluminescent bacteria. The first time was last year at COP21 in Paris. This is a project for the United Nations on ecological change. We have another big event coming up in two weeks. Basically every time we produce more and more bacteria, up to 100 liters, and we can't produce that many liters ourselves. This will keep the team focused for several weeks, but we are still in the research phase and have to stay focused.

Will: Okay, so what drives your research?

Samuel: We do a lot of microbiology research. We did a lot of cloning work for this, and actually to optimize the quantum yield of luciferase, we started a large-scale mutation project, random mutation, because it's both simple and efficient. We have a colony selector to screen large numbers of mutants.

Will: Do you just take a photo, choose the brightest one and then pick it out?

Samuel: Currently, we screen all colonies and then use a 96-well plate reader to detect the light intensity of the colonies. So that's why we were initially interested in having an Opentrons robot. Basically, our goal is to standardize part of our process and automate part of it so that you can prepare a lot of plates with media. In this way, we don't need to manually use multi-channel pipettes every day, let the robot do it. Although simple, adding culture medium to every well every day—we were doing 9 or 10 plates a day—was a lot of work.

Will: Awesome! Just let the Opentrons robot add culture medium to the plate?

Samuel: Yes.

Will: Great, this kind of work shouldn't be done by hand.

Samuel: That’s right. We then used QPix to pick the colonies and place them into the wells of the plate. Afterwards, we grew the freshly picked bacteria in plates and measured the bioluminescence after a few hours. We have a system that measures which one is brighter directly with a plate reader. After that, we take it out, put it on another well plate, and dilute it with the Opentrons robot.

Will: That’s cool, we love doing dilutions.

Samuel: Well, it's kind of like precision picking, turning the plates one by one and diluting. We placed the positive colonies from the first screen in the first row and diluted them for replication. This is to confirm that it is not a misread by the plate reader, but a true positive. This is the first part where we are really interested in using Opentrons robots.

Will: This is great. So, to recap, are Opentrons robots part of your automated mutation process?

Samuel: Yes.

Will: That’s cool! Please tell us what your goals are?

Samuel: When we talk about bioluminescence and intensity, we can really make an analogy to a computer screen. Luminous intensity is not measured in lumens, but in luminous units. Simply put, this is intensity, but it represents brightness per square meter.

Will: Okay, area intensity.

Samuel: Yes.

Will: Is this an important metric for you?

Samuel: Yes. Now we want to increase the light emitted by each bacterium. This means changing the quantum yield, which is the number of photons emitted per reaction. It is known that these luciferases have very poor quantum yields in bacteria.

Will: Did you just say quantum yield?

Samuel: Yes.

Will: Okay, cool. Um, wow?

Samuel: Haha – so that’s the number of photons produced per reaction.

Will: Got it, so these luciferase enzymes are less efficient at producing photons, which is less efficient at emitting light.

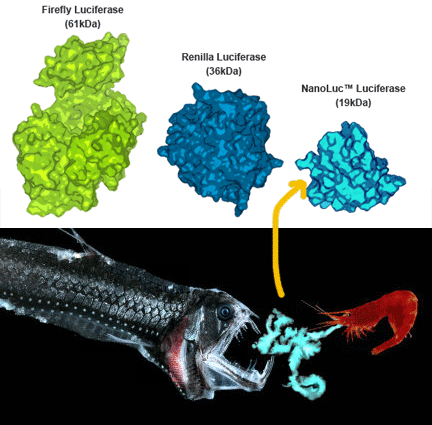

Samuel: Yes. If you look at Promega products, for example.

Will: You mean suppliers?

Samuel: Yes. They sell many types of luciferase. Even their regular products are about 80 times brighter than what we use now. The problem is that we cannot produce the substrate for Promega luciferase in microorganisms because we do not know its biosynthetic pathway.

Will: Well, how do they do it?

Samuel: They make these luciferases chemically, and because these enzymes are for in vitro assays, the purpose is different than what we use them for in bacteria. What this means is that we have to optimize for what we have in bacteria, but the current quantum yield is not efficient. So we need to fundamentally change this. If you look at nature, you'll find some highly efficient mutants. By looking at the structures of these mutants, we can analyze which amino acids have been changed to make them brighter. In other strains, other variants may change their wavelength and become brighter.

Samuel: When you look deeper into nature, you find that YFP sometimes fuses with the lux operon. This fusion allows the yellow fluorescent protein to absorb bioluminescent light and emit yellow light. In this way, we slightly change the emission wavelength of the light, creating an amplified effect. So what we get is a brighter system. This technique is called BRET, or Bioluminescent Resonance Energy Transfer. It is somewhat similar to FRET, but the difference is that instead of energy transfer between fluorophores, we do it between bioluminescence and fluorescence.

Will: Okay, that’s interesting.

Samuel: Also, if you look at some of the small microorganisms in the deep sea, you'll see that they have iridescent colors on some of their hyphae. Maybe I can show you a picture. The fact that they come in all types of colors is incredible.

Will: Wow! This is really shocking!

Samuel: This is bioluminescence. In fact, it is integrated with fluorescence. Bioluminescence has one color of emitted light, which then fluoresces and changes wavelength.

Will: It’s amazing. So you guys are working on this kind of thing?

Samuel: That’s right. So the idea is to get all six colors.

Will: It really looks like neon, and it does. That would be cool.

Samuel: Right now we are actually making colors during the day so you can advertise with your stickers. For example, you can write something completely personalized in red on a sticker. And at night, you can't see red, but you can see the blue-green glow of bioluminescence.

Will: That’s cool!

Samuel: So now during the day it can be blue, yellow, we can get some green, red, and we also have white. So you can see something during the day and then at night you have bioluminescence. Why do we want to have this attribute, this characteristic? Because our first prototype was for a storefront.

Will: When can we see it?

Samuel: Early next year.

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인