-

article · 2025Year39Moon18Day

Flex 工作站在蛋白质定量实验中如何操作更高效?

Read More -

article · 2025Year8Moon17Day

Opentrons Flex 使用中常见问题有哪些?

Read More -

article · 2025Year5Moon16Day

如何通过 Flex 提高蛋白质组学实验产能?

Read More

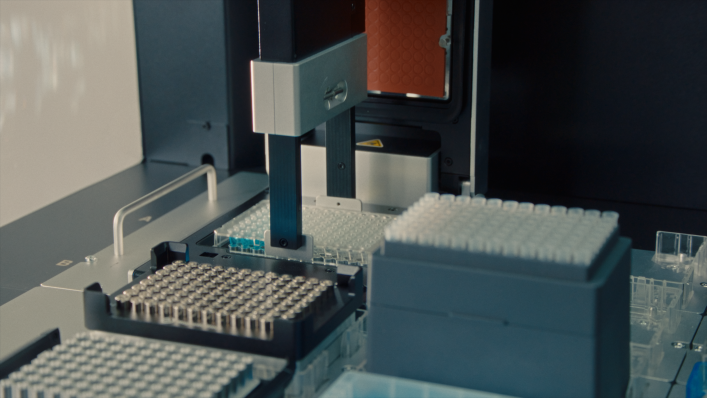

Automatic pipetting equipment, as an important part of modern laboratory automation, realizes automated processing of liquid suction, distribution, mixing and other operations by integrating precise mechanical design, advanced control technology and intelligent operating software. This type of equipment is widely used in biomedical research, drug development, clinical diagnosis, environmental monitoring and other fields, greatly improving the efficiency and accuracy of experiments.

1. Hardware part of automatic pipetting equipment 1. Pipetting module: (1) Robotic arm: The robotic arm is the core component of automatic pipetting equipment and is responsible for driving the pipetting head to move accurately in three-dimensional space. It is usually driven by a high-precision motor and matched with a precise transmission mechanism to ensure that the pipetting head can accurately reach the designated position. (2) Pipetting head: The pipetting head is installed at the end of the robotic arm and is used to absorb and distribute liquids. Depending on the experimental needs, the pipetting head can be single-channel or multi-channel, with tips of different ranges to adapt to the pipetting of different volumes of liquid. (3) Tips: Tips are disposable or reusable parts attached to the pipetting head and used for direct contact with liquids. Tips are usually made from high-quality materials to ensure their chemical stability and sealing. (4) Container positioning device: used to accurately locate the position of experimental containers (such as test tubes, petri dishes, etc.) to ensure that the pipetting head can be accurately inserted into the container for liquid transfer. 2. Monitoring module: (1) Sensors: including pressure sensors, displacement sensors, liquid level sensors, etc., used for real-time monitoring of various parameters during the pipetting process, such as pipetting volume, pipetting speed, liquid level height, etc., to Ensure pipetting accuracy and safety. (2) Camera device: Some high-end automatic pipetting equipment is also equipped with a camera device for real-time monitoring of the pipetting process, making it easier for experimenters to observe and record experimental phenomena. 3. Workbench: (1) The workbench is a support platform for automatic pipetting equipment, used to place containers, accessories and integrated related instruments required for experiments. The workbench usually has adjustable height and angle to adapt to the needs of different experimental scenarios. (2) Safety devices: such as safety doors, emergency stop buttons, etc., used to protect the safety of experimenters and equipment during the experiment. The safety door can prevent contamination caused by liquid splashing or foreign objects flying in, and the emergency stop button can quickly cut off the power of the equipment in an emergency to prevent accidents.

2. Software part of automatic pipetting equipment (1) Control software: Control software is the "brain" of automatic pipetting equipment and is responsible for controlling various operations of the equipment. It usually has a graphical interface to facilitate programming and settings for experimenters. The control software has programming self-test, automatic calculation of actual running time, and provides different levels of automated program editing methods such as menu-based programming tools, logical operations, and source code to meet the needs of different experiments. (2) Data analysis software: Some automatic pipetting equipment are also equipped with data analysis software for processing and analyzing the data generated during the pipetting process. Data analysis software can help experimenters better understand experimental results and optimize experimental conditions.

3. Advantages of automatic pipetting equipment 1. High precision: Automatic pipetting equipment uses high-precision sensors and precise mechanical design to achieve microliter-level liquid distribution, greatly improving the accuracy and repeatability of experiments. This is crucial for experimental procedures that require highly precise control. 2. High efficiency: Compared with traditional manual pipetting methods, automatic pipetting equipment can continuously and quickly perform a large amount of liquid pipetting operations, greatly improving experimental efficiency. At the same time, its multi-channel design allows multiple samples to be processed simultaneously, further improving experimental throughput. 3. Save manpower: Automatic pipetting equipment can automatically complete operations such as liquid pipetting, mixing and distribution, greatly reducing the labor intensity of experimental personnel. Experimenters can devote more energy to core tasks such as experimental design and data analysis. 4. Avoid human errors: Manual pipetting is easily affected by the operator's emotions, fatigue and other factors, leading to experimental errors. Automatic pipetting equipment, through precise mechanical control and electronic monitoring, can effectively avoid errors caused by these human factors and ensure the accuracy of experimental results. 5. Intelligent: Modern automatic pipetting equipment is usually equipped with intelligent operating software, which supports user-defined experimental processes, real-time monitoring of the pipetting process, recording and analyzing experimental data, and other functions. These intelligent features make the equipment easier to operate, manage and maintain. 6. Wide applicability: Automatic pipetting equipment is compatible with a variety of laboratory equipment and consumables to meet the needs of different experimental scenarios. At the same time, its flexible configuration options allow users to customize the equipment configuration according to experimental needs.

Automatic pipetting equipment realizes automated processing of liquid pipetting, dispensing and mixing operations by integrating precision hardware components and advanced control software. Its characteristics of high precision, high efficiency, intelligence and wide applicability make automatic pipetting equipment play an increasingly important role in modern laboratories.

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인