-

article · 2026Year9Moon29Day

Flex蛋白质组学工作站的功能与优势

Read More -

article · 2025Year13Moon27Day

Opentrons Flex蛋白质组学工作站:提升实验室效率的秘密武器

Read More -

article · 2025Year42Moon26Day

Flex 工作站在蛋白质组学实验中的最佳实践是什么?

Read More

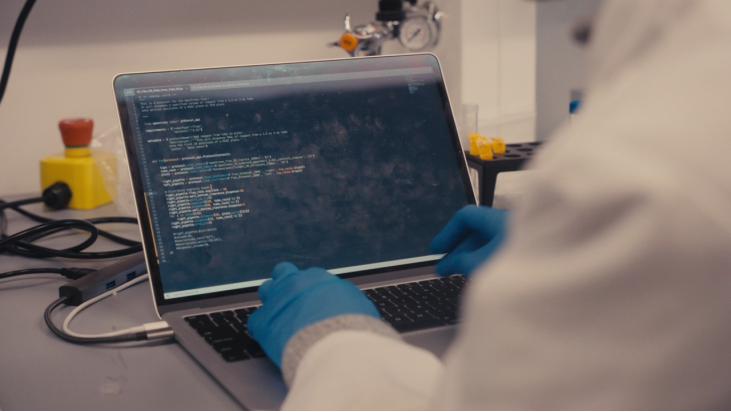

In the laboratory, a complex environment full of challenges and innovations, automated pipetting workstations and manual operations each shine in different application scenarios with their unique advantages. Below, we will analyze these two operating methods in depth from multiple dimensions in order to more fully demonstrate their respective values and applicable fields.

1. Differences between automated pipetting workstations and manual operations 1. Operation efficiency and speed (1) Automated pipetting workstations: Through computer and precision mechanical control, a large number of liquid pipetting operations can be performed continuously, greatly improving experimental efficiency. Its pipetting speed and throughput far exceed that of manual operation, and it can quickly complete a large number of experimental tasks. (2) Manual operation: Limited by human physical strength and attention, the operation speed is relatively slow, and efficiency is easily reduced due to fatigue. Manual operations are particularly time-consuming and laborious when processing a large number of samples. 2. Accuracy and consistency (1) Automated pipetting workstation: Using high-precision sensors and control systems, it can ensure the accuracy and consistency of each pipetting. The system will also perform quality detection on the absorbed liquid, such as volume error, concentration error, etc., further improving the accuracy of the experiment. (2) Manual operation: Although trained experimenters can achieve a certain degree of accuracy, the consistency and accuracy of their operations are difficult to maintain for a long time due to the influence of environment, emotion, fatigue and other factors. 3. Labor intensity and cost (1) Automated pipetting workstation: Automated operations reduce the labor intensity of experimental personnel, allowing them to have more time to focus on experimental design and data analysis. At the same time, due to the reduction of manual operations, labor costs are also reduced. (2) Manual operation: Experimenters need to perform repetitive liquid transfer work for a long time, which is labor-intensive and prone to operational errors due to fatigue. In addition, as labor costs rise, so do the costs of manual operations. 4. Risk of cross-contamination (1) Automated pipetting workstation: The use of closed system and disposable pipette designs can effectively reduce the risk of cross-contamination and ensure the reliability of experimental results. (2) Manual operation: In the process of manually changing tips and transferring samples, it is easy to cause cross-contamination due to improper operation, affecting the accuracy of experimental results. 5. Applicability and flexibility (1) Automated pipetting workstation: It can be customized according to experimental needs and is suitable for a variety of experimental scenarios and types of experiments. At the same time, its highly integrated liquid handling, sample transfer, data analysis and other functions provide experimenters with an efficient, accurate and convenient experimental experience. (2) Manual operation: Although it has a certain degree of flexibility, it is unable to handle complex experiments or a large number of samples. In addition, manual operation is difficult to achieve high-precision automated control and data analysis.

2. Applicable scenarios for automated pipetting workstations: 1. High-throughput experiments: When a large number of samples need to be processed, automated pipetting workstations can significantly improve experimental efficiency and reduce manual operation time and costs. 2. High-precision requirements: For experiments that require highly precise control of liquid volume, concentration and other parameters, automated pipetting workstations can provide higher accuracy than manual operations. Its high-precision sensors and control system ensure the accuracy and consistency of each pipetting and reduce experimental errors. 3. Reduce cross-contamination: In experiments that need to avoid cross-contamination, the advantages of automated pipetting workstations are particularly obvious. Its closed system and disposable tips can effectively reduce the risk of contamination and ensure the reliability of experimental results. 4. Long-term continuous operation: For experiments that require long-term continuous liquid processing, automated pipetting workstations can reduce the labor intensity of experimenters and avoid operational errors caused by human factors.

3. Suitable scenarios for manual operation: 1. Small-scale experiments: When the scale of the experiment is small and the number of samples is not large, manual operation may be more convenient and economical. At this time, experimenters can flexibly perform liquid pipetting and other operations without using complex automated equipment. 2. Special sample processing: In some special cases, such as when processing samples that are volatile, easily oxidized, or have special properties, manual operation may be more appropriate. Experimenters can choose appropriate operating methods and conditions based on sample characteristics to ensure the accuracy of experimental results. 3. Teaching demonstration: In laboratory teaching, in order to allow students to better understand and master experimental skills, manual operation may be more intuitive and effective. Through teachers' demonstrations and students' hands-on operations, students' understanding of experimental principles and operating procedures can be deepened. 4. Limited resources: In laboratories with limited resources or tight budgets, manual operation may be a more economical option. At this time, experimenters need to make full use of existing resources and improve experimental efficiency by optimizing experimental design and operating procedures.

Automated pipetting workstations and manual operations each have their own advantages and applicable scenarios. The selection should be comprehensively considered based on factors such as the specific needs, scale, complexity, and resource conditions of the experiment. For experiments that require high efficiency, high precision, and large sample processing, automated pipetting workstations are a better choice; while for experiments that are small-scale, highly flexible, or cost-constrained, manual operation may be more appropriate. In practical applications, flexible selection and optimized configuration can be made according to the specific conditions and needs of the laboratory.

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인