-

article · 2025Year25Moon24Day

article · 2025Year25Moon24DayFlex工作站如何应对高通量蛋白质样本制备?

Read More -

article · 2025Year17Moon24Day

article · 2025Year17Moon24Day如何用Flex蛋白质组学工作站完成一次完整样本制备?

Read More -

article · 2025Year10Moon24Day

article · 2025Year10Moon24DayFlex蛋白质组学工作站对质谱前处理的优化

Read More

The automatic liquid dispensing system, as an indispensable core equipment in contemporary laboratories, achieves efficient and precise control of the liquid separation and transmission process by virtue of its excellent precise pressure and flow rate control capabilities. This technological innovation not only greatly improves the accuracy and efficiency of experimental operations, but also widely penetrates into diverse fields such as life sciences, pharmaceutical chemistry, and environmental monitoring, becoming a powerful driving force for scientific exploration and technological progress.

1. Principle of automatic liquid dispensing system 1. Pressure difference drive The automatic liquid dispensing system uses pressure difference to drive the flow of liquid. This usually includes two modes: positive pressure and negative pressure: (1) Positive pressure mode: A certain pressure is provided through a syringe pump or compressed gas to make the liquid to be separated flow at a preset flow rate. A syringe pump can ensure that liquid is dispensed at a constant rate by precisely controlling its pushing force. (2) Negative pressure mode: Negative pressure is generated through the equipment's own structure or a vacuum pump, and the liquid to be separated is sucked into the pipeline for flow. This method is suitable for scenarios where liquid needs to be drawn, such as drawing a specific amount of liquid from a container for distribution. 2. Precision flow rate control system Equipped with a precise flow rate control system, the flow rate can be adjusted according to experimental needs. Precise control of liquid separation and transmission is achieved by precisely adjusting devices such as pressure valves, valves and pumps. This precise control ensures a highly consistent amount of liquid dispensed each time, improving experimental accuracy and repeatability. 3. Liquid separation principle In automatic liquid separation systems, a variety of liquid separation principles are usually used to achieve liquid separation. Among them, centrifugal separation is the most common method. It uses centrifugal force to separate solid particles or precipitates from the liquid, and then transfers the supernatant liquid to the corresponding receiving container through pressure difference. In addition, other liquid separation principles such as filtration and extraction may also be used, depending on the needs of the experiment and the properties of the liquid. 4. Motor and mechanical control In order to achieve accurate distribution of liquid, automatic liquid dispensing systems usually use power devices such as motors to drive the liquid distribution mechanism. For example, the rotation of the motor drives the piston push rod to move up and down, thereby controlling the amount of liquid sucked in and spit out. This mechanical control ensures precise and stable liquid dispensing. 5. Intelligence and automation Modern automatic dispensing systems often integrate intelligence and automation technology. They have touch screens or microcomputer control systems that can automatically complete dispensing tasks through preset programs. At the same time, the system can also record various parameters and results during the liquid dispensing process in real time, and generate detailed reports to facilitate data analysis and traceability by experimenters.

2. Technical characteristics of the automatic liquid dispensing system 1. High precision: Using a high-precision pump or pneumatic system as the power source, combined with a precise flow control algorithm, to achieve precise distribution of liquid. 2. High efficiency: Automated operation reduces manual intervention and waiting time, and improves experimental efficiency. 3. Wide applicability: supports the use of a variety of liquid containers and adapters to meet different experimental needs. 4. Easy to operate: Equipped with an intuitive user interface and control software, users can flexibly set parameters according to experimental needs. 5. High safety: Equipped with a variety of safety protection mechanisms, such as overload protection, leakage detection, etc., to ensure the safety and reliability of the experimental process.

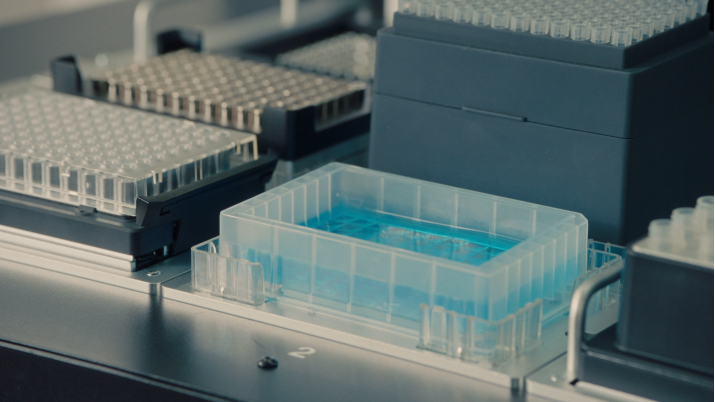

3. Examples of Brands and Models There are many brands and models of automatic liquid dispensing systems on the market, such as Opentrons’ Flex fully automatic pipetting workstation, which not only supports basic automatic liquid dispensing functions, but also has extensive scalability and customizability. . Users can choose the appropriate pipette configuration and plate space according to the specific needs of the laboratory to meet the needs of different experimental scenarios. In addition, the Flex workstation is compatible with a variety of laboratory equipment and consumables, further improving its applicability and flexibility.

Automatic liquid dispensing systems play an increasingly important role in modern laboratories due to their high precision, high efficiency, wide applicability and ease of operation. With the continuous advancement of science and technology and the increasing demand for experiments, the automatic liquid dispensing system will continue to be upgraded and improved to provide more convenient and efficient solutions for scientific research work.

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인