-

article · 2026Year2Moon5Day

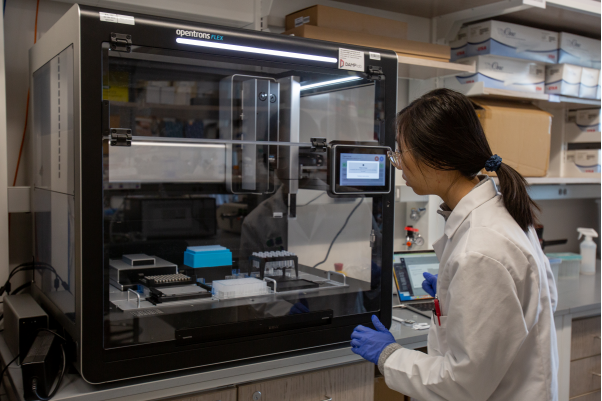

Opentrons Flex 高通量 NGS 工作站安装与调试全流程

Read More -

article · 2026Year57Moon5Day

实验室如何利用 Opentrons Flex 实现高质量数据输出

Read More -

article · 2026Year57Moon4Day

Opentrons Flex vs 其他自动化 NGS 工作站对比评测

Read More

A sample pretreatment workstation is a device used in the laboratory to preprocess biological, chemical or environmental samples for subsequent analysis or experiments. This kind of workstation usually consists of multiple modules that can be configured and customized according to different application requirements.

1. Main components of conventional sample preprocessing workstation 1. Sample input system: responsible for receiving and recording samples to be processed. Typically includes autosamplers, barcode scanners and sample identification systems to ensure proper identification and tracking of samples. 2. Sample storage and management module: used to store and manage samples, including refrigeration, freezing and normal temperature storage. Samples can also be classified, sorted and labeled to quickly find the required sample during subsequent processing. 3. Sample pretreatment module: The core part is responsible for performing various pretreatment operations on samples, such as dilution, mixing, centrifugation, filtration, extraction, enrichment, etc. These operations can be customized and adapted to experimental needs. 4. Automated liquid handling system: Responsible for precise liquid operations during sample pretreatment, such as pipetting, dispensing, adding reagents, etc. Typically includes one or more programmable robotic arms, pumps, and valves, as well as racks for storing reagents and consumables. 5. Detection and analysis module: used for real-time monitoring and analysis of pre-processed samples to understand the quality and concentration of the samples. Typically includes analytical instruments such as spectrometers, mass spectrometers, and chromatographs, as well as software for data processing and reporting. 6. Data management and control system: Responsible for data collection, processing and storage of the entire sample preprocessing workstation. The running status of each module can be monitored in real time to ensure the smooth progress of the experiment. In addition, it can be integrated with other laboratory equipment and systems through the network to achieve remote control and data sharing. 7. Waste liquid treatment and safety system: Responsible for processing waste liquid generated during the experiment to ensure the safety and environmental protection of the laboratory. It usually includes equipment such as waste collectors, filters, and sterilizers, as well as safety sensors for detection and alarms. 8. User interface and operation panel: Human-computer interaction interface, responsible for displaying information such as experimental progress, parameter settings, and fault diagnosis. Users can operate and monitor via touch screen or computer software.

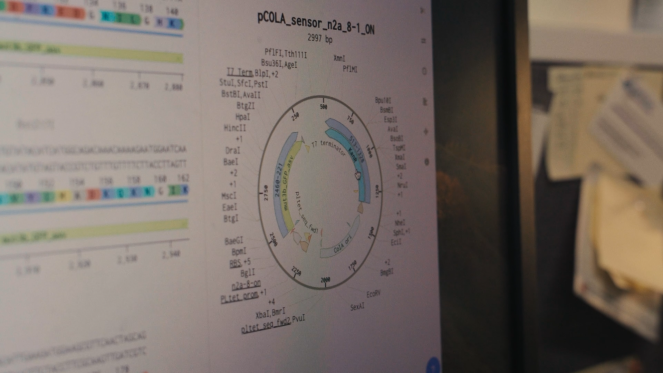

2. Main components of sample preprocessing of Opentrons Flex fully automatic pipetting workstation 1. High-precision pipetting module: (1) Equipped with single-channel, 8-channel and 96-channel pipettes, using air replacement technology to achieve 1-1000 μL High-precision pipetting within the range. (2) The pipette has a built-in smart sensor that supports automatic calibration, real-time positioning and error detection to ensure accurate and reliable pipetting. (3) A high-precision motor drives the robotic arm to achieve precise movement in three-dimensional space to meet different sample preprocessing needs. 2. Efficient workbench and plate position system: (1) Provide a stable working platform, reduce cross-contamination, and facilitate operation. (2) The upgraded plate space includes 12 main deck plate positions and 4 additional plate positions, supporting high-throughput sample processing. (3) Reasonably lay out the plate position system to improve experimental efficiency and facilitate the placement of experimental equipment and functional modules such as sample plates, reagent plates, and pipette tips. 3. Advanced control and software system: (1) The control system integrates motor control units, sensor interfaces and communication interfaces to ensure accurate execution of operating instructions and monitoring of experimental parameters. (2) The software system adopts the Opentrons ecosystem, provides a graphical user interface (GUI), and supports touch screen or remote computer control. (3) The intelligent graphical prompt function makes the operation intuitive and easy to understand. It is also compatible with AI tools such as ChatGPT to improve protocol development efficiency and experimental innovation capabilities. 4. Expandable additional function modules: (1) Supports a variety of additional function modules, such as UV sterilization module, temperature control module and thermal cycle module. (2) Select and configure functional modules according to experimental needs to expand the workstation functions and application scope, such as ensuring a pure experimental environment, precise temperature control, and supporting temperature cycle experiments such as PCR.

3. Which sample types are suitable for the Flex pipetting workstation? 1. Biomolecular samples: (1) Nucleic acid samples: The Flex pipetting workstation can be combined with a nucleic acid extraction kit to automatically complete the extraction of DNA and RNA. This is crucial for genomics, transcriptomics and other studies, and can efficiently extract high-quality nucleic acid samples for subsequent experiments. (2) Library preparation: In next generation sequencing (NGS), Flex pipetting workstation can be used for automated library preparation. It processes samples accurately to ensure library quality and homogeneity, thereby improving the accuracy and reliability of sequencing results. 2. Cell samples: (1) Flex pipetting workstation can be used for sample processing in cell culture, cell sorting and other experiments. Through automated operations, human errors can be reduced and the repeatability and accuracy of experiments can be improved. 3. Protein samples: (1) In proteomics research, the Flex pipetting workstation can be used for protein purification, quantification and other experiments. Its high precision and flexibility make protein sample processing more efficient and accurate. 4. Other biological samples: (1) Flex pipetting workstation can also be used to process other types of biological samples, such as microbial samples, tissue samples, etc. By combining different kits and experimental procedures, automated processing of a variety of biological samples can be achieved.

Opentrons Flex fully automatic pipetting workstation sample pretreatment workstation provides powerful tools for research in the field of life sciences with its high-precision pipetting module, efficient workbench and plate position system, advanced control and software system, and scalable additional functional modules. Technical support. It can not only significantly improve experimental efficiency and reduce human errors, but also further stimulate the innovation potential of experimental design through an intelligent operating interface and compatibility with AI tools.

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인