-

article · 2026Year48Moon30Day

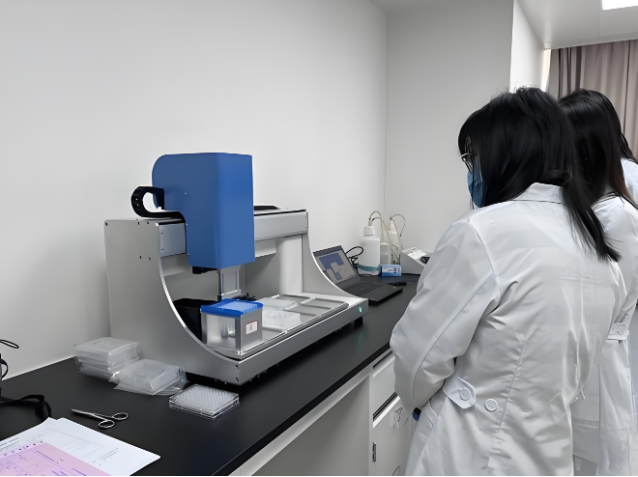

Flex蛋白质组学工作站如何帮助加速蛋白质样品分析?

Read More -

article · 2026Year9Moon29Day

Flex蛋白质组学工作站的功能与优势

Read More -

article · 2025Year13Moon27Day

Opentrons Flex蛋白质组学工作站:提升实验室效率的秘密武器

Read More

Pipetting stations, especially highly specialized pipetting workstations, play a key role in laboratory automation processes, focusing on precise and efficient liquid handling tasks. They show rich and colorful forms based on diversified classification dimensions. Each type contains unique design concepts and performance advantages, and together they form an indispensable part of the laboratory automation operation system.

1. Types of pipetting stations 1. Viewed from the perspective of automation: (1) Manual pipetting workstation: As the most basic form, it relies on the direct intervention of the operator. Although it is easy to operate and cost-effective, it cannot process a large number of pipetting stations. samples or when pursuing a high degree of accuracy. (2) Semi-automatic pipetting workstation: It finds a balance between automation and manual operation. Some of the automated functions reduce the manual burden while retaining the necessary flexibility. It is suitable for scenarios that require certain manual intervention. (3) Fully automatic pipetting workstation: It represents the pinnacle of automation technology and can independently complete the entire process from liquid absorption to transfer, greatly improving work efficiency and accuracy. It is an ideal choice for high-throughput and high-precision experiments. 2. Starting from the processing capabilities and technical characteristics: (1) Single-channel and multi-channel pipetting workstations: Single-channel is suitable for experiments with small batches and high-precision requirements; while multi-channel is famous for its parallel processing capabilities, which can significantly shorten the experiment cycle, especially suitable for large-scale sample processing. (2) High-precision adjustable pipetting workstation: Integrated with advanced liquid control technology, it can achieve precise transfer of micro- to large-volume liquids and meet the stringent requirements for liquid handling accuracy in different experiments. 3. Customized design for specific application fields: (1) Dedicated pipetting workstation: such as a pretreatment workstation specially designed for the construction of PCR reaction systems, or an automated workstation for complex liquid-liquid extraction processes. These equipment are designed according to specific experiments. The process has been deeply optimized to improve experimental efficiency and result reliability.

Q1. What should I do if the pipette tip of the pipetting station is blocked? 1. Inspection and confirmation (1) Confirm blockage: First, confirm that the pipe head is indeed blocked, which means it cannot absorb or discharge liquid normally. (2) Reason for observation: Observe whether there are obvious blockages on the tip of the pipette, such as solid particles, protein precipitation or other impurities. 2. Clean the pipette head (1) Gently disassemble: Follow the disassembly steps of the pipette and gently remove the pipette head from the pipette. Be careful not to use excessive force during disassembly to avoid damaging the pipette or pipette tip. (2) Clean the pipette head: If there is a visible blockage on the pipette head, you can use an appropriate solvent (such as deionized water, ethanol, etc., selected based on experimental requirements and solvent compatibility) for cleaning. Use tools such as a straw or fine needle to gently pick out the blockage, taking care to avoid damaging the internal structure of the tip. After cleaning, dry the gun tip with a clean paper towel or cotton swab to ensure that there is no residual solvent. 3. Inspection and replacement (1) Check the gun head: After cleaning, check whether the gun head returns to normal and ensure that there are no blockages and the internal channels are unobstructed. (2) Replace the pipette head: If the pipette head is damaged or cannot be cleaned, replace it with a new pipette head in time. 4. Special situation handling (1) Internal mechanical failure: If the pipette head is blocked, it is caused by an internal mechanical failure of the pipette. (Such as piston wear, spring failure, etc.), you need to contact the manufacturer or professional maintenance personnel for inspection and repair. (2) Complex situations: If the clogging problem is difficult to solve or involves complex experimental requirements, it is recommended to consult laboratory technicians or relevant experts for help.

Q2. Why is the pipette tip not recognized? 1. Hardware and physical factors (1) Tip mismatch: Reason: The size, shape or material of the pipette and tip do not match, resulting in the inability to correctly identify or fix the tip. Solution: According to the model and specifications of the pipette, select a tip that matches it. Usually, the pipette instructions or packaging will have information about adapter tips. At the same time, ensure that the suction head has no deformation, wear or contamination. (2) Incorrect installation: Reason: The pipette is not correctly inserted or fixed during installation, causing the pipette to be unrecognizable. Solution: Reinstall the tip, making sure it fits tightly into the pipette interface and is not loose or skewed. Some pipettes may require turning or pressing a specific button to secure the tip. (3) Foreign body interference: Reason: There are foreign particles, such as dust, fibers, etc., between the pipette or the tip cone, which hinders the correct installation and identification of the tip. Solution: Clean the pipette and tip cone to make sure there are no foreign particles interfering with it. This can be gently cleaned with a clean cotton swab or vacuum cleaner. 2. Software and setting factors (1) Recognition system failure: Reason: The recognition system inside the pipette failed and the tip could not be correctly identified. Solution: Check whether the pipette's software settings and recognition system are working properly. You can try restarting the pipette or updating the software version to solve the problem. If the problem persists, you may need to contact the manufacturer or professional maintenance personnel for repair. (2) Calibration problem: Reason: The pipette has not been calibrated for a long time or the calibration is inaccurate, resulting in the inability to correctly identify the tip. Solution: Perform calibration operations according to the instructions of the pipette to ensure that the parameters of the pipette are set correctly. If you are not sure how to perform calibration, you can consult the manual or consult the manufacturer's technical personnel. 3. Other factors (1) Power supply and connection problems: Reason: The pipette’s power supply is unstable or poorly connected, causing the identification system to fail to work properly. Solution: Check whether the power cord and plug of the pipette are well connected and whether the power supply is stable. You can try changing the power cord or plug to solve the problem. (2) Environmental factors: Reason: Unfavorable factors such as too humid laboratory environment, too high or too low temperature may affect the normal operation of the pipette. Solution: Ensure that the laboratory environment meets the working requirements of the pipette, such as temperature, humidity and other parameters should be within the specified range. If the environmental conditions cannot meet the requirements, corresponding measures can be taken to improve them.

Q3. What is the use of air in front of the pipetting station? 1. Ensure accurate aspiration: Excluding the air before using the pipette can ensure that when the liquid is aspirated, the pipette tip is filled with the liquid to be measured and not air. This avoids inaccurate pipetting volumes due to air entrapment. 2. Improve precision: The presence of air will increase uncertainty and errors during pipetting. By pre-discharging air, these uncertainties can be reduced, thereby improving pipetting precision and repeatability. 3. Prevent the generation of bubbles: During the liquid transfer process, if air is contained in the pipette tip, bubbles may form in the liquid. These bubbles will not only affect the accuracy of pipetting, but may also have a negative impact on subsequent experimental results. Front air exhaust can effectively avoid this problem. 4. Protect the pipette: Long-term use of a pipette with air may cause damage to its internal structure and sealing. Pre-exhaust air can reduce wear and damage to the pipette and extend its service life.

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인