Flex应用专题 | 解锁蛋白质谱前处理自动化的无限潜能

Check the Details-

article · 2025Year3Moon9Day

清洗微孔板的具体步骤是什么

Read More -

article · 2025Year56Moon8Day

磁珠分选是什么

Read More -

Press release · 2025Year40Moon8Day

云端相约 | 邀您共同解锁蛋白质谱前处理自动化无限潜能

Read More

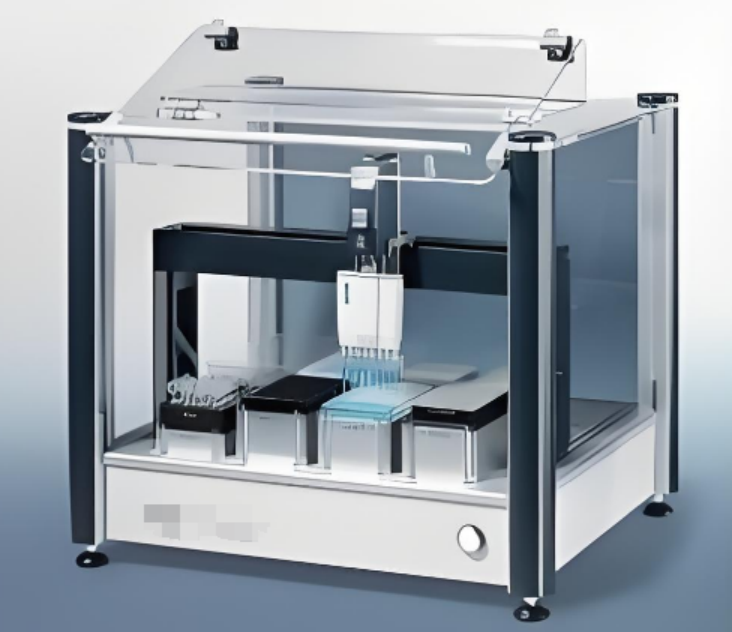

The liquid handling equipment mainly provided by the pipetting workstation has the characteristics of high throughput, high precision, high automation, high compatibility, and high cost performance, and can realize continuous gradient dilution, liquid distribution, addition, and combination between 96 and 384 microwell plates. and continuous gradient dilution and other functions, then, let’s take a look at the composition and usage precautions of the pipetting workstation.

The pipetting workstation is also called an automated liquid processing platform. Compared with traditional pipetting tools, the pipetting workstation can automatically complete high-precision liquid processing tasks such as gradient dilution, pipetting, and merging liquids. Used in parallel with an analyzer, the automatic pipetting station enables accurate detection of targets.

Pipetting workstation consists of:

1. The pipetting workstation generally consists of five parts: pipetting module, monitoring module, workbench, safety door and software.

2. The main function of the pipetting module is to complete liquid processing tasks such as sample gradient dilution, pipetting and merging.

3. The monitoring module can monitor the status of the pipetting module to ensure the precision and accuracy of pipetting.

4. Containers, components and matching related instruments required for experiments can be placed on the workbench.

5. The workstation is equipped with a safety door to prevent liquid spillage from causing contamination and foreign matter from rushing in during the experiment, ensuring the safety of operators.

6. The software can control the pipetting station and its integrated related components and equipment, control liquid flow, reagent addition, proportional dilution or various integrated components, instruments, etc.

Precautions when using the pipetting workstation:

1. Pay attention to protecting the pipe tip (suction head) when using it, and do not touch other objects;

2. During the use of the machine, please wait patiently for the reaction of the machine and do not stop at any time to avoid affecting the life of the machine.

3. Keep the working environment clean to prevent deviation in results.

4. Be careful when taking out the pipette tip. Make a rough adjustment first, quickly hang the liquid suction gun on the pipette head, keep a distance of 1cm, and then slowly insert the liquid pipette gun into the pipette head; (The shipping appendix of the position parameter table is in operation. If there is any deviation, fine-tuning is required.)

5. When the pipette head sucks the second liquid, the pipette head needs to be replaced to avoid cross-contamination;

6. The software is open and supports the correction of liquid volume and position. If there is any deviation, the value can be changed and corrected in the setting interface.

7. When setting the position, be sure to start from the zero point and make sure to reset to ensure position accuracy and reproducibility.

8. Drainage without suction means no empty suction was performed before suction. Please confirm first that the vacuum suction operation is being executed.

The above introduces the composition and usage precautions of the pipetting workstation. If you need to know more, you can contact us at any time! Our company has many years of experience and we are always looking forward to your inquiries.

The experienced service team and strong production support team provide customers with worry-free order services.