-

article · 2025Year57Moon22Day

如何利用 Flex 实现蛋白质样品的高通量纯化?

Read More -

article · 2025Year16Moon20Day

Opentrons Flex 的自动吸光度读板机使用技巧有哪些?

Read More -

article · 2025Year13Moon19Day

Flex 的磁力模块能处理哪些复杂样品?

Read More

The structural research of high-precision pipetting pumps is undoubtedly a comprehensive challenge spanning multiple high-precision fields such as precision machinery, fluid dynamics, electronic control, and materials science. This topic requires not only in-depth exploration of professional knowledge in various fields, but also the seamless integration and innovative application of this knowledge. In the field of precision machinery, the structural design of high-precision pipetting pumps needs to achieve micron or even nanometer-level processing accuracy to ensure the precise coordination and stable operation of key components such as pump heads, pistons, and valves. This not only tests the technical level of mechanical processing and assembly, but also promotes the continuous progress of material science and manufacturing technology to meet the performance requirements in extreme working environments.

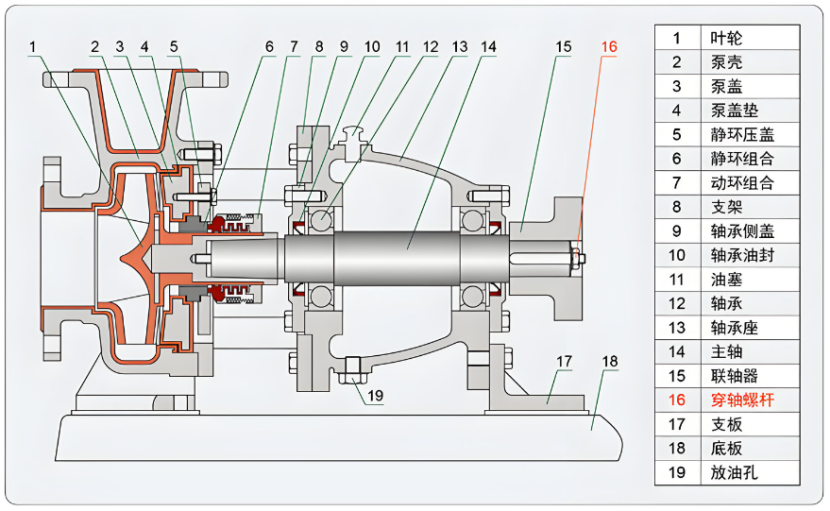

1. Core components and functions 1. Pump head (1) Structure: The pump head is the core component of the pipetting pump and usually consists of an inlet pipe, an outlet pipe and an elastic membrane. There is a small hole in the center of the elastic membrane, and the liquid inlet pipe and the liquid outlet pipe are connected to both sides of the small hole. (2) Function: The pump head realizes the suction and discharge of liquid through the compression and release of the elastic membrane. When the elastic membrane is compressed, a negative pressure is formed in the pump head, and the external liquid is sucked into the pump head under the pressure difference; when the elastic membrane is released, the pressure in the pump head increases and the liquid is discharged. 2. Piston and transmission mechanism (1) Structure: The piston is a key component that drives the compression and release of the elastic membrane. It is usually made of precision-machined metal or ceramic materials. The transmission mechanism includes motors, connecting rods, gears and other components, which are used to convert the rotational motion of the motor into the linear motion of the piston. (2) Function: Driven by the transmission mechanism, the piston makes reciprocating motion in the pump head, thereby achieving precise removal of liquid. The accuracy and stability of the transmission mechanism directly affect the pipetting accuracy of the pipetting pump. 3. Valve system (1) Structure: The valve system includes an advanced valve and a drain valve, which are used to control the suction and discharge of liquid respectively. Valves are usually composed of precision-machined valve bodies and valve cores, and the switching action is achieved through electromagnetic control or mechanical control. (2) Function: The valve system ensures that liquid can only flow in one direction during pipetting, preventing backflow and contamination. At the same time, pipetting accuracy can be further improved by precisely controlling the switching time and speed of the valve. 4. Sealing system (1) Structure: The sealing system includes sealing seats, sealing hoops, O-rings and other components, which are used to ensure the sealing between the pump head, liquid inlet pipe, liquid outlet pipe and other components. (2) Function: The sealing system prevents liquid leakage and gas from entering the inside of the pump head, ensuring the stability and reliability of the pipetting process. At the same time, the quality of the sealing performance also directly affects the pipetting accuracy and the service life of the pump. 5. Control system (1) Structure: The control system includes electronic control unit (ECU), sensors, display screens and other components, which are used to realize automatic control and precise measurement of pipetting pumps. (2) Function: The control system sets parameters such as pipetting volume and pipetting speed according to experimental requirements, and monitors various parameter changes during the pipetting process in real time through sensors. At the same time, the control system also has fault diagnosis and alarm functions to ensure the safe operation of the pipetting pump.

2. Structural design features 1. Precision processing: Each component of a high-precision pipetting pump must undergo precision processing and strict inspection to ensure that its dimensional accuracy and surface finish meet the requirements. 2. Material selection: Key components such as the pump head and piston are usually made of high-performance materials that are corrosion-resistant and wear-resistant to improve the service life and stability of the pump. 3. Modular design: Pipetting pumps usually adopt a modular design, which facilitates disassembly and replacement of parts and reduces maintenance costs and time. 4. Automated control: Through the integration of electronic control units, sensors and other components, automatic control and precise measurement of pipetting pumps are realized, improving experimental efficiency and accuracy.

3. Research and development directions 1. Improve pipetting accuracy: By optimizing the pump head structure, improving the transmission mechanism, and improving valve control accuracy, the pipetting accuracy and stability of the pipetting pump can be further improved. 2. Expand the scope of application: Develop high-precision pipetting pump products with different functions for different fields and experimental needs to meet market demand. 3. Intelligent development: Apply advanced technologies such as artificial intelligence and big data to the research and development of high-precision pipetting pumps to achieve intelligent control and optimization of the pipetting process.

The structural research of high-precision pipetting pumps is a complex topic involving multiple fields. By continuously optimizing structural design, improving processing accuracy and material performance, and strengthening research and development work in intelligent control, the performance and reliability of high-precision pipetting pumps can be further improved, providing more accurate and efficient experimental analysis and scientific research work. solution.

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인