Flex应用专题 | 解锁蛋白质谱前处理自动化的无限潜能

Check the Details-

article · 2025Year3Moon9Day

清洗微孔板的具体步骤是什么

Read More -

article · 2025Year56Moon8Day

磁珠分选是什么

Read More -

Press release · 2025Year40Moon8Day

云端相约 | 邀您共同解锁蛋白质谱前处理自动化无限潜能

Read More

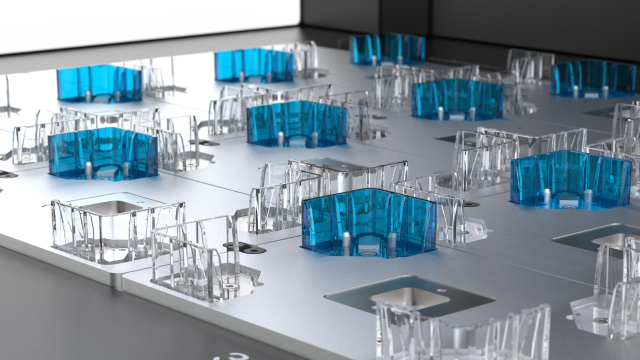

The working principle of the liquid handling workstation is mainly based on the precise control, distribution and mixing of liquids. Its core lies in the combination of automation technology and high-precision pipetting technology. Through precise mechanical structure, control system and liquid transmission system, precise control of liquid is achieved. It can suspend the experimental substances in the liquid medium and realize the experimental process through the flow and mixing of the liquid.

1. Workflow of the liquid handling workstation 1. Sample loading: First, the user places the sample to be processed and the required reagents in the designated location of the liquid handling workstation, such as microplates, test tubes, etc. 2. Program setting: The user sets the pipetting parameters, operating steps and processes required for the experiment through the LCD screen, touch screen or computer interface. These parameters include pipetting volume, pipetting speed, pipetting depth, target position, etc. 3. Automated operation: The liquid processing workstation automatically completes operations such as sample absorption, transfer, distribution and mixing according to the preset program. These operations are usually achieved through equipment such as high-precision pipetting heads, robotic arms, solenoid valves, and air pumps. (1) Pipetting head: The high-precision pipetting head is a key component of the liquid handling workstation. It can accurately control the pipetting volume and transfer the liquid from the source container to the target container. (2) Robotic arm: The robotic arm is responsible for moving the pipetting head to a designated position to achieve automatic suction and distribution of samples. (3) Solenoid valves and air pumps: These devices are used to control the flow and mixing of liquids to ensure the accuracy and stability of operation. 4. Online detection and analysis: Some advanced liquid processing workstations are also equipped with optical detection systems, which can conduct online detection and analysis of processed samples, such as absorbance, fluorescence, etc., to provide more data support for experiments. 5. Data recording and reporting: Liquid handling workstations usually have data recording functions and can automatically record key parameters and results during the experiment. Users can also generate experimental reports as needed to facilitate subsequent data analysis and processing.

2. Technical advantages of the liquid handling workstation 1. High precision: The liquid handling workstation adopts high-precision pipetting technology to ensure the accuracy and repeatability of experimental results. 2. Automation: Automated operation greatly reduces the labor intensity of experimental personnel and improves experimental efficiency. 3. Flexibility: Users can customize the operating procedures according to experimental needs to meet diverse experimental needs. 4. Compatibility: Liquid handling workstations are usually compatible with multiple types of liquids and consumables, making it convenient for users to conduct diverse experiments.

The liquid handling workstation achieves precise control and automated processing of liquids through precise mechanical structures, control systems and liquid transfer systems. The core of its working principle lies in the combination of high-precision pipetting technology and automation technology, which provides strong support for experimental research and production.

The experienced service team and strong production support team provide customers with worry-free order services.