-

article · 2026Year54Moon31Day

Flex蛋白质组学工作站的热振荡模块如何加速蛋白质检测

Read More -

article · 2026Year48Moon30Day

Flex蛋白质组学工作站如何帮助加速蛋白质样品分析?

Read More -

article · 2026Year9Moon29Day

Flex蛋白质组学工作站的功能与优势

Read More

As pharmaceutical manufacturers focus on tighter control of their processes, online real-time microbial testing provides them with transparency and immediate feedback on incidents or deviations. A leading biotechnology company used the 7000RMS analyzer to immediately identify problems with its water system before and during maintenance and was able to quickly troubleshoot the problem and return the system to control.

Conductivity and total organic carbon (TOC) are two compendial process analytical parameters for which online/online measurement have been the accepted standard for decades. However, when it comes to monitoring microbial contamination in WFI or PW, the market has relied on laboratory methods developed over a century ago. The need for the ability to monitor bioburden contamination in real-time is recognized, recognized and endorsed by the pharmaceutical industry, pharmacopeias and regulatory agencies. Integrated online bioburden measurement offers significant advantages in process control.

With the FDA and EMA promoting Process Analytical Technology (PAT) programs to encourage the use of online instrumentation for real-time process control, pharmaceutical manufacturers are exploring ways to bring microbial testing online for conductivity and total organic carbon (TOC). They continue to rely on laboratory-based methods to control this compendial parameter, while looking for online methods for process control, transparency and risk mitigation. In addition to monitoring trends in this parameter, these users leverage online measurements to immediately identify any issues that are occurring so that they can proactively respond to any disturbances.

Continuous monitoring using real-time data A leading biotechnology company installed the 7000RMS on its PW system as a process control tool. The system has a dual RO configuration where the user can periodically switch between the two RO modules. After one year of using the 7000RMS analyzer, the user has defined a baseline for the automatic fluorescence unit (AFU) trend displayed on the analyzer. Users maintain stable measurements over a baseline, indicating that the system is in control.

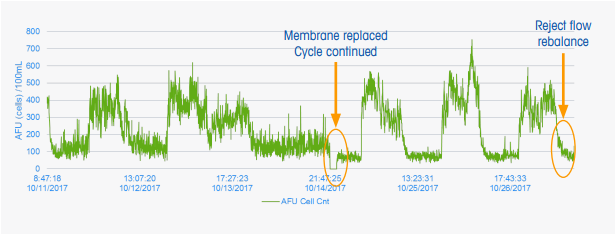

Troubleshoot quickly and get feedback immediately. However, on October 11, 2017, the AFU measurements began to fluctuate above baseline, and a periodic pattern was observed, as shown in Figure 1. Additionally, one of the RO modules began to display higher measurements while online, indicating the need for immediate maintenance on the water system. This pattern is seen due to the continuous measurement of 7000RMS, which would be ignored if only monitored by plate counts. On October 14, 2017, the user decided to replace the membrane as a corrective action. However, when the system was brought back online after replacing the membrane, the cycling pattern continued, indicating that the problem had not been resolved. Therefore, a second corrective action was taken and the waste stream was rebalanced.

The 7000RMS Microbial Detection Analyzer improves process control and production efficiency by continuously monitoring results every two seconds to optimize disinfection frequency and rinse times. Control product quality using high-sensitivity technology counting individual microorganisms as small as 0.3 µm. Minimize risk and reduce costs Real-time monitoring eliminates time waiting for results. Trend data enables people to react before out-of-spec events occur.

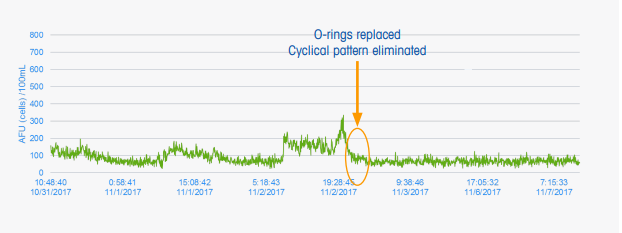

After this troubleshooting step, the AFU baseline count returned to normal and continued to show stable measurements for several days. However, on November 2, 2017, the cyclical pattern reappeared, albeit at lower levels. In an effort to proactively fix the issue before it becomes more serious, users investigated the steps taken during the October maintenance. Through the troubleshooting process, the user was able to trace the root cause to an incorrectly installed O-ring that was replaced when the membrane was replaced. This resulted in biofilm forming in the system, but contamination from this biofilm was quickly caught thanks to the 7000RMS’s real-time monitoring. After the O-ring was repaired, the system returned to normal and the AFU count returned to baseline, as shown in Figure 2.

Implementing Real-Time Monitoring on a Global Scale This troubleshooting exercise demonstrates to users the capabilities of the 7000RMS analyzer and the benefits it provides through transparency into the user's water system. This motivates users to maintain tight control over their water systems and reduce risks associated with undetected events. ---Based on this experience, the user decided to install 7000RMS in all factories around the world. The user's goal is to achieve the same process control in all plants, thereby reducing risk. Titanium digs words; Hechuang digs words; Yiqisuan digs words.

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인