Flex应用专题 | 解锁蛋白质谱前处理自动化的无限潜能

Check the Details-

article · 2025Year3Moon9Day

清洗微孔板的具体步骤是什么

Read More -

article · 2025Year56Moon8Day

磁珠分选是什么

Read More -

Press release · 2025Year40Moon8Day

云端相约 | 邀您共同解锁蛋白质谱前处理自动化无限潜能

Read More

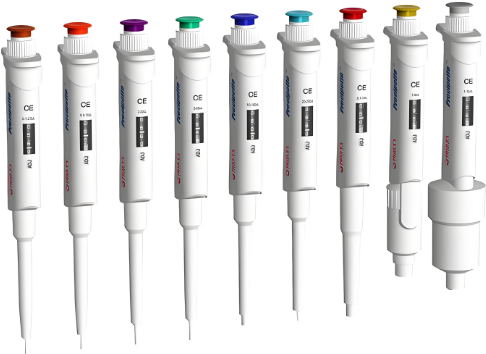

In most laboratories, accurate and repeatable dispensing of liquids is important for experiments. And, micropipettes have been a mainstay in chemistry and biology laboratories for decades, used to deliver smaller volumes of liquid accurately and accurately. Micropipettes are used in various types of laboratories including microbiology, environmental science, medicine, chemistry, chemistry, diagnostic laboratories, etc. Despite the importance of accurate liquid handling in research and diagnosis, little attention has been paid to pipettes. Micropipettes come in a variety of sizes, depending on the volume that can be transferred. Commonly used micropipettes in laboratories are P-10, P-20, P-100, P-200 and P-1000. Numbers indicate the maximum volume that can be transferred (in microliters).

1: Structure of a micropipette Most micropipettes have the following basic parts: Volume adjustment knob – rotate to adjust the volume Volume indicator Plunger button – aspirate and dispense tips Eject button – discard the tip after use Volume adjustment Knob Plastic Shaft Tip Ejector Arm – Discard tips after use To draw liquid into the pipette’s shaft, a disposable plastic tip is attached to the shaft. There are different types of tips in different sizes and colors depending on the micropipette used and the volume to be dispensed. Common tips are: large blue – 200-1000µL, small yellow – 2-200µL, small white – <2µL

2: Usage of Micropipettes Micropipettes are used to deliver accurate volumes, which depends on the following conditions: Position: During aspiration, the pipette should remain vertical. Moving the pipette 30°C away from vertical may result in aspiration of 0.7% additional liquid due to hydrostatic pressure. Also always keep the pipette in an upright position when storing. Pre-wet/pre-rinse tips – Before pipetting, always remove the old tip and place a new tip on the shaft. Inconsistencies between samples may occur due to prewetting techniques.

Release Plunger – A smooth and consistent pipetting rhythm is recommended to increase accuracy and precision. Sudden release of the plunger can cause liquid to hit inside the pipette. This can cause liquid to accumulate inside the instrument and be transferred to other samples, resulting in sample volume changes and the potential for cross-contamination.

Immersion depth – Pipette tips should only be inserted into containers containing approximately 1-3mm of liquid. Because, if you immerse the nib beyond the nib, the liquid may stick to the nib and transfer with the nib, or if the nib is not immersed far enough, air may be drawn into the nib, which may cause erroneous results.

Equilibration time – mitigates the effects of thermal expansion that can affect volume delivery. The tip, pipette, liquid being transferred, and the transfer container itself can all be equilibrated to the same temperature. Pipette Micrometer Settings – The recommended volume range of a pipette may change radically and may even fail to effectively change the volume delivery performance.

3: How to Handle Micropipette In order for the pipette to function properly, it is important to take the following precautions very carefully: Never adjust the volume outside the range of the micropipette. Do not adjust the micropipette below zero microliters. Never adjust P20 above 20μ, P200 above 200μl, and P1000 above 1ml. Never force the volume adjuster dial. Do not drop the pipette. When using a pipette, always use smooth movements. There should be no "pop" sound. When not in use, always place the micropipette upright on the stand installed on your workbench. Always choose the appropriate size pipette for the volume to be measured. There are two stops on the micropipette plunger: Slowly depress the plunger to the first stop to aspirate the sample. This pushes air out of the pipette tip, preparing the correct amount of liquid to be aspirated. This is the initial resistance point. Insert the tip into the liquid and slowly release the plunger to aspirate the sample. The second step is dispensing; carefully push the plunger down past the initial resistance until it makes contact with the body of the pipette. Applying pressure to the second stop dispenses the correct volume of fluid.

4: Cleaning and Maintenance of Micropipettes Regular preventive maintenance of pipettes will help to better reduce failures and keep them in good operating condition. Maintenance schedules may vary depending on the importance of the pipette, the type of solution being transferred with the pipette, and the age of the pipette. Regular maintenance includes the following steps: 1. Disinfect the outside of the pipette: Wipe the pipette with a detergent solution and dry the pipette with a lint-free cloth before and after use. Check the general appearance of the pipette: 2. The plunger should be straight and free of corrosion or cracks, and the measuring window should be clear and properly aligned. Pipettes should be free of physical or chemical damage, cracks or breaks. 3. Disassemble and clean the pipette: Remove the tip ejector Separate the lower half of the pipette from the upper half Sterilize each component removed from the pipette Remove the seal and O-ring assembly Visually inspect for worn and cracked parts Clean the air passages with a long, fiber-free cotton swab dipped in cleaning solution (inspect the nose cone) Inspect the piston assembly for bends, corrosion, or cracks Rinse with distilled water and air dry 4. Replace O-rings and seals pieces. 5. The pipette manufacturer's user manual should be consulted for lubrication (if applicable). 6. Reassemble the pipette and check functionality 7. Place the calibrated volume of pipette upright on a rack overnight using a micrometer. 8. Calibrate/verify pipette performance

5: Calibration of micropipette In order to perform good function, the micropipette needs to be calibrated correctly every three months. Calibration can be easily performed in the laboratory using gravimetric methods. Principle: The density of distilled water is constant at constant temperature and atmospheric pressure. The volume of water can be determined by weighing the dispensed water. When determining water volume, measurement accuracy is affected by ambient temperature, atmospheric pressure and relative humidity. Therefore, these factors are often combined together to give the Z factor, which is used to calculate water volume. The calculated amount of water is then compared to the theoretical amount to determine the accuracy and accuracy of the pipette

Micropipette Calibration Procedure Since temperature affects the density of water and thus the theoretical weight, please estimate the water temperature. Place the empty weighing boat on the scale. The tare weight is zero. Add appropriate amount of water via micropipette. Record the weight and repeat nine times for a total of 10 readings. Calculate the mean and standard deviation of the readings. For correct calibration of a micropipette: the coefficient of variation (CV) calculated by dividing the standard deviation by the mean should be less than 1%. The accuracy of the micropipette, calculated by dividing the actual mean by the theoretical mean, should be between 99-101%. If the micropipette is no longer calibrated correctly, send it to the manufacturer for calibration. Technicians often need to adjust (tighten or loosen) some screws to compensate for the bulk.

The experienced service team and strong production support team provide customers with worry-free order services.