-

article · 2026Year9Moon29Day

Flex蛋白质组学工作站的功能与优势

Read More -

article · 2025Year13Moon27Day

Opentrons Flex蛋白质组学工作站:提升实验室效率的秘密武器

Read More -

article · 2025Year42Moon26Day

Flex 工作站在蛋白质组学实验中的最佳实践是什么?

Read More

Ergonomics (also known as human factors) is a worker-centered science that integrates principles and data from various related disciplines and applies them to work design. Ergonomics focuses on the interaction between people and their work environment, tools and equipment, technology, and other workers. Ergonomic design takes into account human physical and cognitive abilities, adapting jobs to workers based on their strengths and weaknesses, and can balance the use of technology and automation with human skills. Humans are very good at flexible decision-making, execution of different tasks and integration of workflows. Automation and machinery support simple, highly repetitive, or difficult tasks.

The goal of ergonomic design is to enhance human performance and well-being in the world of work (Wilson, 2000). Doing so also improves the quality and efficiency of the work system. Ergonomics contributes to the economic health and sustainability of organizations by improving worker sustainability and maximizing performance. Other contributions to the bottom line include reduced costs from lost productivity, quality defects, injuries and employee turnover. Investments in simple engineering interventions, such as appropriate pipetting tools and improved workspace design, combined with efficient protocols and continuous improvement processes, can help reduce costs for organizations.

1. Applying ergonomic design in the laboratory Manual micropipetting is repetitive in nature, using primarily the thumb to apply force to aspirate and dispense small amounts of liquid. Prolonged pipette use is associated with physical discomfort and injury. Hand and shoulder disorders were found to be more common among female laboratory technicians than among female state employees in general (Björksten et al., 1994), with pipette users reporting elbow and hand discomfort significantly more frequently compared to a control population higher (David et al., 1997). The force required to operate a pipette is a factor that affects the risk of musculoskeletal disorders (MSD), such as tendinitis, muscle strains, and carpal tunnel syndrome. When using manual pipettes, the maximum total hand force is typically found when the tip is attached and the liquid is fully dispensed (e.g., blow-out); depending on the design of the pipette, tip ejection may require greater force than dispensing (Lu et al. People, 2008). The repeatability of manual pipetting force is also of concern. Tasks that require the application of high forces at high repetition rates have a significantly greater risk of MSD than either non-repetitive high-force tasks or repetitive low-force tasks (Silverstein, 1987). Other research clarifies that for carpal tunnel syndrome, applied manual force is the primary risk factor for injury and that repetition is a risk factor only if the force exerted is “forceful” (Kapellusch et al., 2015).

Some common pipetting practices that increase exposure to these ergonomic risk factors include:

2. Human-centered design in the laboratory When selecting pipettes, consider the following features to minimize the impact of ergonomic risk factors: 1> Finger hooks. Pipettes with finger hooks facilitate passive holding, minimizing grip force; swivel finger hooks improve the fit of the pipette for users with a variety of hand sizes. 2>Grip diameter. The pipette should fit comfortably in the hand; for users with larger hands, a larger diameter pipette should be considered. 3>Rotate the head. Multichannel pipettes with rotating heads promote a neutral wrist posture by rotating the pipette to align with the plate rather than bending the wrist. 4>Plunger force. Examine the force with which single-channel and multi-channel pipettes depress the plunger with liquid at the tip; compare forces between different pipettes to find the minimum force; consider using an electronic pipette for repetitive tasks. 5>Plunger height. Check plunger height across the entire volume range (plungers at the high end of the range will be taller) to minimize thumb overextension. A biomechanical model based on grip strength and force efficiency found that the optimal plunger height is 3 cm for men and 2 cm for women (Kim and Freivalds, 2018). 6>Weight. Lighter pipettes require less muscle strength to hold; electronic pipettes may be heavier due to batteries and motors; for multichannel pipettes, look at how to balance the weight distribution in the hand to minimize Wrist pressure. 7>Suction head connection. Pipette cone and tip design, tip fit and connection method all affect the force required to connect a tip - using an inappropriate tip increases grip strength to connect and thumb pressure to eject the tip; use low force connections Method-designed pipettes, or pipettes with tactile or auditory connection feedback, may reduce exposure. 8>The suction head pops up. Strength can vary greatly between different brands of pipettes and can affect thumb and wrist fatigue and strain, especially with multichannel pipettes; electronic pipettes with electronic tip ejection can eliminate the entire Stress in the pipetting cycle; manual pipettes using the low-force tip ejection method reduce thumb pressure. 10>Volume adjustment and programming menu. The pipette with clear display is intuitive and easy to read, promotes a neutral neck posture and reduces cognitive load. 11>Symmetry. The pipette design with display allows for ambidextrous use, making it more versatile. 12>Accuracy and precision. Consult the user manual to confirm that the calibrated pipette meets necessary specifications to maintain quality and reduce rework.

Electronic pipettes reduce force, repetition and increase efficiency with built-in features and pipetting programs. Electronic pipettes should be considered for tasks involving higher repeatability or greater force, such as:

Ergonomic Pipetting Practices Based on known pipetting risks and common techniques that increase exposure, the following practices are recommended:

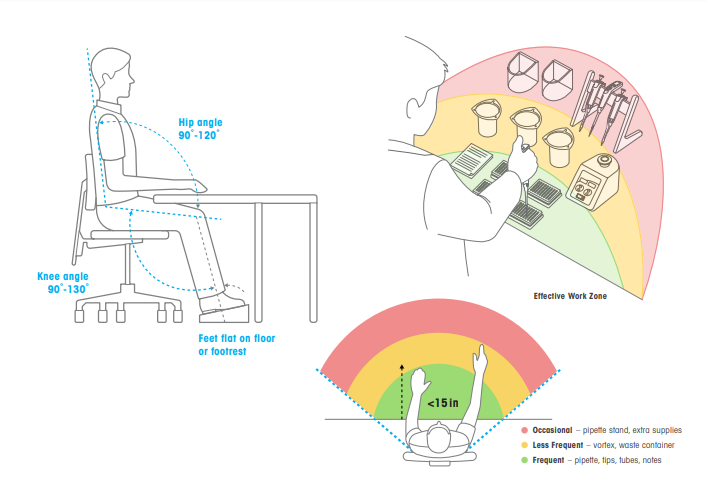

3. The connection between workstation setup and posture The design of the physical workspace and the tools used determine work posture. The position of the work surface determines the position of the arms, shoulders and back. The height and size of the chair determines the position of the legs and back. The position of the visual target determines the position of the head, neck and back. Working in non-neutral or awkward postures can increase fatigue, discomfort, and risk of MSD. As mentioned previously, these negative physical outcomes can also negatively impact task performance. Common awkward postures observed in the laboratory are neck bent forward to view well plates at the bench, rounding of the back when sitting on a laboratory stool, and arms reaching forward and upward when using serological pipette aids Extend the thumb and flex the wrist when inserting into the hood, and when micropipetting.

Well-designed workstations provide adequate clearance and support for the body and allow workers easy access to their tools and supplies. Because humans come in all different sizes, designing adjustability into workstations is ideal, and adjusting workstations to properly fit each individual is critical to promoting a neutral body posture.

Before you start using your new workbench or work cover, take the time to follow these simple setup tips to improve comfort and task performance:

Standing work is ideal for jobs that involve larger movements, increased mobility, or require a large number of supplies. Standing is also a good solution when the chair cannot be adjusted high enough to keep your elbows above the work surface. As with sitting, the work surface should be at or slightly below elbow level to allow for a relaxed shoulder posture and a straight neck during standing laboratory work. For taller people, a standard work surface may be well below elbow level, which can lead to awkward neck and back posture. Addressing this mismatch by elevating your work surface to a high platform allows your hands to work between shoulder and waist level, promoting a neutral neck and back posture. Given the precise nature of pipetting and laboratory work, the visual demands of the task often pull the head downward or forward, creating awkward neck and back postures. Using ergonomic tools to position the pipette container at an angle can improve neck posture by making your work easier to see. A variety of angled racks are available for test tubes, well plates, test tube racks, Petri dishes, flasks and bottles. Using the Orifice Direction Card behind the Orifice Board can further enhance neck posture by improving vision.

4. Invest in talent Investing in solutions such as ergonomic pipetting tools, improved workspace design, and appropriate technical training can reduce costs for your organization. A simple cost-benefit analysis shows that ergonomic interventions often pay for themselves within one year (Goggins et al., 2008). The basic monetary benefits of ergonomic interventions include injury costs avoided through reduced risk exposure and time saved through increased efficiency or productivity. Injuries have direct costs, such as medical bills, insurance premiums, government fines (such as OSHA), lawsuits, and the use of disability benefits. In addition, workplace injuries have indirect costs, including reduced productivity, increased paperwork, employee dissatisfaction, reduced motivation, reduced work quality, and increased worker turnover. Indirect costs tend to be greater than direct costs and their severity is inversely proportional to the severity of the injury. The less severe the injury, the higher the ratio of indirect costs to direct costs. Twenty lab technicians work in the lab, earning $40 an hour for full-time work. In this laboratory, there was a 3-year history of concomitant MSD, including hand/wrist strains (2 cases), tendonitis (3 cases), and carpal tunnel syndrome (1 case). The five 3-electronic pipette starter kit cost the company $17,500. Additional fee is $450.

Reducing injuries and increasing productivity are not the only quantifiable benefits of ergonomic interventions. Benefits commonly reported also include reduced lost work days, restricted work days, and workers' compensation expenses. Other benefits related to quality, turnover and absenteeism are also frequently reported (Goggins et al., 2008). Injuries occur in the parts of our bodies that demand the most—those areas that are used most frequently and with the greatest force. However, the risk of injury depends on more factors than just the accumulated physical exertion during work.

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인