Flex应用专题 | 解锁蛋白质谱前处理自动化的无限潜能

Check the Details-

article · 2025Year3Moon9Day

清洗微孔板的具体步骤是什么

Read More -

article · 2025Year56Moon8Day

磁珠分选是什么

Read More -

Press release · 2025Year40Moon8Day

云端相约 | 邀您共同解锁蛋白质谱前处理自动化无限潜能

Read More

The modular liquid workstation is an automatic workstation specially designed for pharmaceutical, biotechnology and research applications. It integrates liquid transportation, magnetic suction, vibration, heating and other functions, and can automatically complete a variety of complex liquid processing tasks. Such as protein purification, nucleic acid extraction, drug screening, etc. Its modular design allows users to select and configure different functional modules according to actual needs, thereby adapting to different experimental and production needs. By integrating multiple functional modules, efficient automation of the liquid treatment process is achieved.

1. Main functional modules 1. Pipetting module: The pipetting range is wide, usually covering liquid volumes from microliters to tens of milliliters. The pipetting accuracy is high and can meet the needs of precise experiments. Supports multi-channel pipetting, such as 4 channels, 8 channels or even higher, to improve processing efficiency. Equipped with liquid level detection function to ensure the accuracy of pipetting operations. 2. Magnetic separation module: mainly used for protein purification, nucleic acid extraction and other applications based on magnetic bead method. Through the action of magnetic field, the magnetic beads and liquid can be quickly separated and the purification efficiency can be improved. 3. Temperature control module: Provides precise temperature control function to meet the temperature requirements of different experiments. The temperature control range is wide, usually covering multiple intervals from low temperature to high temperature. The heating and cooling speed is fast, and the set temperature can be reached quickly. 4. Oscillation module: used to effectively mix samples to ensure uniform reaction. The oscillation speed is adjustable to adapt to different experimental needs. 5. Barcode recognition module: It can recognize one-dimensional and two-dimensional codes at the same time to realize automatic identification and tracking of samples. Improve the accuracy and traceability of experimental operations. 6. Opening/closing module: automatically opens and closes the sample tube to reduce manual intervention. Compatible with all brands of sample tubes currently on the market, improving the versatility of the equipment. 7. Centrifugal module: centrifuge the liquid to achieve solid-liquid separation or liquid stratification. The centrifugation speed and time are adjustable to meet the needs of different experiments. 8. Image acquisition module: high-resolution industrial-grade camera to realize information tracking of experimental processes. Can be used to record experimental processes, analyze experimental results, etc. 9. Robotic arm module: used to transfer consumables to third-party equipment outside the workbench, such as microplate readers, PCR machines, etc. Improve the flexibility and automation of experimental operations.

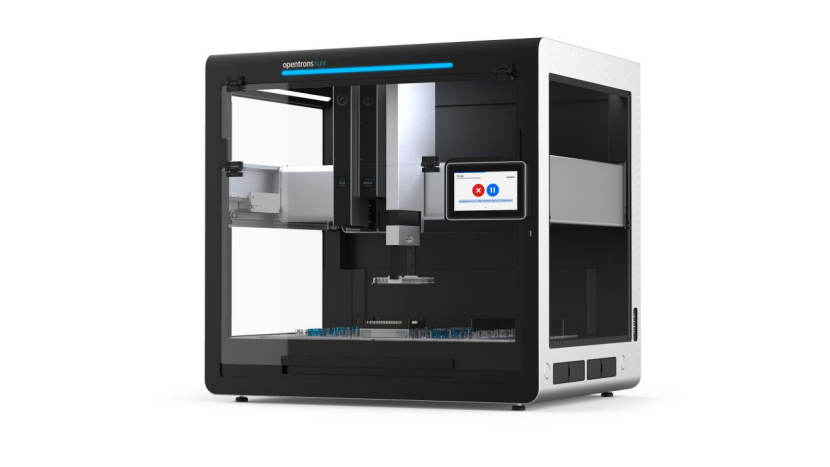

2. Brand recommendation Opentrons has a modular liquid workstation, one of the most representative products is the Opentrons Flex fully automatic pipetting workstation. Through its modular design, this workstation integrates a variety of functions, such as liquid transportation, magnetic suction, vibration, heating, etc., and can automatically complete a variety of complex liquid processing tasks, such as protein purification, nucleic acid extraction, drug screening, etc. The main advantages of Opentrons Flex fully automatic pipetting workstation include: 1. High flexibility: users can select and configure different functional modules according to actual needs to adapt to different experimental and production needs. 2. High-throughput: Flex pipette uses air displacement technology, which can perform high-precision pipetting of 1-1000 μL, and is equipped with intelligent sensors with automatic calibration, real-time positioning and error detection functions. 3. Easy to operate: Equipped with a 7-inch LCD touch screen, which is made of anti-scratch and anti-damage LCD material. Users can complete experimental settings by simply touching the screen. At the same time, the software system has intelligent graphic prompts, making the operation simple and easy to understand. 4. Space upgrade: The Flex deck has 12 main deck slots and 4 additional deck slots for placing pipette tips, laboratory equipment and functional modules to better meet the needs of scientific researchers.

The modular liquid workstation is an automation platform that combines high integration and excellent flexibility. Its exquisite modular design accurately meets diverse experimental and production needs. This innovative design not only simplifies the complex liquid handling process, but also greatly improves the efficiency and accuracy of operations in an unprecedented way.

The experienced service team and strong production support team provide customers with worry-free order services.