-

article · 2025Year35Moon24Day

使用 Flex 工作站可以提高实验重复性吗?

Read More -

article · 2025Year47Moon23Day

Flex 工作站废料自动清理功能如何设置?

Read More -

article · 2025Year57Moon22Day

如何利用 Flex 实现蛋白质样品的高通量纯化?

Read More

As the pharmaceutical and biotech industries continue to innovate to meet patient needs for therapies, the pace of development of novel therapies is accelerating. The industry has witnessed the fruitful results of innovations such as cell therapies and gene therapies, which have brought hope of recovery to countless patients. However, many of these treatments require a 2-4 day turnaround time to ensure the treatment is effective. Traditional microbial detection methods such as plate counting are inadequate when it comes to reducing the risk of contamination during this process, as the incubation period requires at least 5 days to obtain results, detection capabilities are low, and actual microbial levels are easily underestimated.

New Process Control Strategies These limitations of the plate counting method have forced a rethinking of control strategies to ensure that the process is always under control, thereby reducing the risk of contamination. Rapid microbial detection methods (RMM), including process water, are key to this overall process control strategy. While plate counting can confirm water quality at the end of the incubation period, knowing that the process is under control using RMM measurements allows the industry to minimize the risk of releasing product within the required turnaround time. However, the industry has been looking to regulators to give their views and guidance before fully adopting such RMMs. Regulators, on the other hand, recognize that the need for innovative therapies requires innovation in the manufacturing, processing and monitoring of raw materials. After approving these innovative treatments, regulators want to ensure patient safety is not compromised during treatment. They are also aware of the limitations of current validated microbial detection methods and have indicated that they are open to considering other technologies and methods as part of an overall process control strategy. While not all regulatory agencies and pharmacopoeias worldwide have responded to these concerns, the harmonization process among the various regulatory agencies and pharmacopoeias suggests that this openness will continue to grow globally as industry adopts a global supply perspective. reflected within the scope.

United States Pharmacopeia (USP) The USP is aware of the limitations of traditional plate counting methods. In Chapter <1223> it specifically refers to these limitations in various terms, as follows: • “Research on the recovery of microorganisms from drinking and environmental waters has shown that reporting cell count estimates as colonies Conventional plate counting of forming units (CFU) can recover 0.1-1% of the actual microbial cells in a sample. ”• “If the growth, nutrients, or culture conditions provided to the microorganisms are insufficient to promote colony recovery and colony growth, then even if viable cells are present. cells, the result may also be 0 CFU or No Growth." With this in mind, USP encourages other measurement methods and techniques to be considered as part of an overall control strategy. These include: • Laser-induced cytofluorescence technology • Detection of vitally stained cells by solid-phase and fluid fluorescence microscopy • Measurement of ATP levels by bioluminescence These methods are RMMs that allow for faster detection of any microbial contamination incident by immediately detecting any exceedances respond. Although plate counting is currently the only validated water release method, USP and FDA encourage users to use a holistic process control approach that incorporates other technologies. Statistical methods are also provided in USP <1223> that can be used in setting baselines and alarm limits for such surrogate measurement signals.

European Medicines Agency (EMA) EMA has clearly expressed its encouragement to consider RMM as part of overall process control. EMA underlines this position in GMP Annex 1 “FAQs on the production of water for injection” and gives the following statement: • “The use of alternative/rapid microbiological testing methods should be considered as part of the overall control strategy of the system.” • “The use of rapid microbiological detection methods should be considered as part of a control strategy to assist in rapid response to system degradation.” With such a clear statement on how to utilize RMM in overall process control, EMA encourages users not to simply Relies on plate counting. It should be pointed out again that although the plate counting method is still the only validated water release method at present, the validation of other methods is also under study, and EMA will continue to encourage users to incorporate RMM into overall process control.

Federal Drug Administration (FDA) As mentioned previously, regulators have realized that traditional plate counting methods are not rapid enough, so some approved therapies require rethinking process control strategies. Given that FDA investigators are often on the front lines of conducting factory inspections, the industry is eager to hear from the FDA about RMMs and their use in the process. FDA's recognition is crucial to fully demonstrate the correctness of the industry's implementation of RMM.

During the Q&A session at the 14th Annual PDA Global Medicinal Microbiology Conference in Bethesda (USA), an FDA representative was asked: “If I were still performing traditional plate counts on my water system, But I want to run the new RMM at the same time for comparison, so why? Do I need to validate it? What are the problems with this additional approach?” In response, the FDA panel welcomed the technology and said that the PAT initiative encourages the use of complementary rapid methods in addition to traditional validated methods. Microbial detection methods for overall process control. The FDA clarified that this was the original intention of the PAT initiative in terms of encouraging new technologies to meet industry needs. As long as a proven method is used to release water, it essentially provides a "safe haven" for users as they explore ways to better control their processes. This clearly demonstrates the FDA's attitude toward RMM. FDA recognized RMM consistent with its PAT initiative, which aims to achieve better process control and reduce reliance on process-collected samples that would only reveal problems when the product is already affected. To further clarify FDA's position, an independent Process and Environmental Monitoring Methods (PEMM) Collaborative Working Group met with FDA's Emerging Technologies Team to discuss RMM. PEMM's membership includes many major pharmaceutical industry stakeholders as well as suppliers associated with RMM. The working group described the advantages of laser-induced fluorescence (LIF) technology and asked the FDA to provide a position statement on the use of this technology as a process control tool. LIF is the core technology in the 7000RMS™ analyzer.

Summary of regulatory opinions on the use of rapid microbiological testing methods

In its response, the FDA publicly supported the use of this technology (LIF) as a process control tool used in parallel with traditional plate counting as a first step. This underlines their response at the PDA conference where they encouraged the use of RMM as a complement to traditional validated methods such as plate counting. In addition, compared to collecting samples, the RMM system can continuously monitor the total amount of microorganisms in water with a higher sensitivity than traditional methods. Continuous microbial monitoring using data trending and analysis capabilities provides real-time validation that can be used to improve overall process understanding and process control. In addition, as real-time microbiology technology becomes more widely used as a process control tool, the FDA expressed its willingness to discuss various methods to confirm that this technology can be used as a potential alternative to current validated methods. The PEMM Working Group and other industry groups will continue to work with FDA to define these validation procedures so that RMM can be used as a validated method. Until then, however, the FDA encourages the use of RMM as a process control tool in parallel with traditional plate counting.

The growing recognition and encouragement of statements and responses from various agencies clearly demonstrates that RMM can play an important role in the overall process control strategy. Regulators encourage their use in parallel with validated methods such as plate counting so that processes are proactively monitored and users can respond quickly to exceedances, thereby preventing contamination events. This recognition of RMM is critical to meeting the growing demand for innovative therapies, so industry should adapt its processes to meet the requirements.

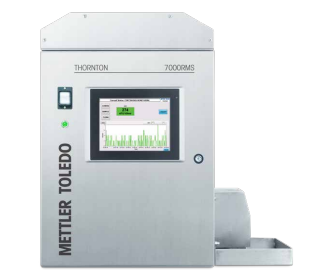

The 7000RMS Microbial Detection Analyzer improves process control and production efficiency. Continuous monitoring with results every two seconds can optimize system processes.

Count individual microorganisms as small as 0.3 µm for high sensitivity control of product quality.

Minimize risk and reduce costs Real-time monitoring eliminates the need to wait for results. Predictive trend data enables you to react to exceedance events before they occur.

Comply with global regulatory requirements Regulatory agencies encourage the use of alternative rapid microbiology methods.

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인