Flex应用专题 | 解锁蛋白质谱前处理自动化的无限潜能

Check the Details-

article · 2025Year56Moon8Day

磁珠分选是什么

Read More -

Press release · 2025Year40Moon8Day

云端相约 | 邀您共同解锁蛋白质谱前处理自动化无限潜能

Read More -

article · 2025Year27Moon6Day

微孔板振荡器在工作站中的应用

Read More

The high-throughput pipetting workstation is an advanced laboratory equipment that integrates high-precision sensors, intelligent control systems and automation technology. It can automatically complete various experimental operations such as pipetting, weighing, and mixing, which greatly improves the efficiency of experiments. efficiency and accuracy.

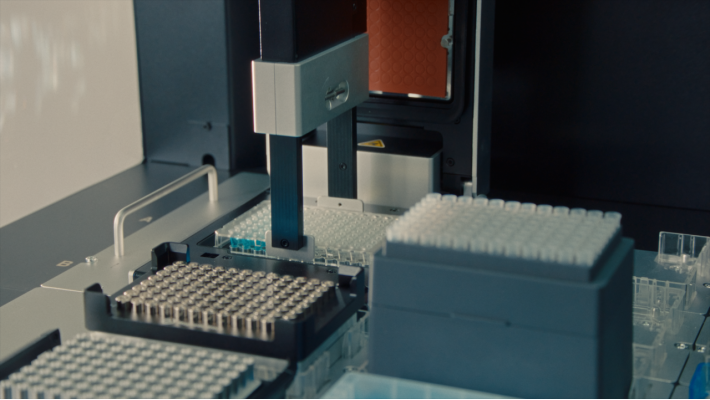

1. Composition of a high-throughput pipetting workstation 1. Pipetting module (1) Pipette head: The pipette head is a key component to achieve liquid transfer in a high-throughput pipetting workstation. Depending on experimental needs, pipette heads with different volume ranges can be replaced to meet liquid transfer needs ranging from microliters to milliliters. These pipette tips are typically designed to be disposable or reusable to ensure experimental hygiene and accuracy. (2) Syringe pump and stepper motor: Syringe pump and stepper motor are the power sources that drive the pipette head for liquid transfer. The stepper motor drives the piston in the syringe pump to reciprocate by precisely controlling the rotation angle and speed, thereby achieving the suction and discharge of liquid. (3) Slide table and slide block: The slide table and slide block are the key components connecting the stepper motor and pipette head. The stepper motor is connected to the screw through a coupling and drives the screw to rotate at the same frequency. The slider is connected to the screw and slides forward along the fixed axis. This design allows the rotary motion of the stepper motor to be converted into linear reciprocating motion of the slider, thereby driving the pipette head for precise liquid transfer. 2. Control system (1) Microprocessor: such as STM32 microprocessor, which is the "brain" of the high-throughput pipetting workstation. It is responsible for receiving and executing instructions set by the user, and controlling the operation of stepper motors, syringe pumps and other components. The microprocessor ensures the accuracy and stability of liquid transfer through precise algorithms and logical judgment. (2) Programming interface: High-throughput pipetting workstations are usually equipped with user-friendly programming interfaces, allowing users to customize experimental processes, set pipetting parameters, etc. as needed. These parameters include pipetting volume, pipetting speed, pipetting mode, etc., and users can flexibly adjust them according to experimental needs. 3. Monitoring module (1) Sensor: non-contact sensors such as infrared confocal optical sensors are used to monitor key parameters such as liquid level height and liquid volume in the tube. These sensors can provide real-time feedback of status information during the liquid transfer process to ensure the accuracy and safety of the experiment. (2) Safety doors and protective covers: High-throughput pipetting workstations are usually equipped with safety facilities such as safety doors and protective covers. The safety door can lock the operating status of the workstation when it is closed, preventing liquid from spilling or foreign objects from flying in due to accidental opening during the experiment. The protective cover is used to protect key components such as the pipetting module and control system from external interference and damage. 4. Workbench and accessories (1) Workbench: used to place containers, accessories and integrated related instruments required for experiments. The design of the workbench usually takes into account the convenience and safety of experimental operations, such as anti-slip, anti-splash, easy to clean and other characteristics. (2) Accessories: accessories such as containers, suction heads, waste liquid collection boxes, etc., are used to assist in completing liquid transfer operations. These accessories are usually designed to be detachable and replaceable, allowing users to flexibly configure and use them according to experimental needs.

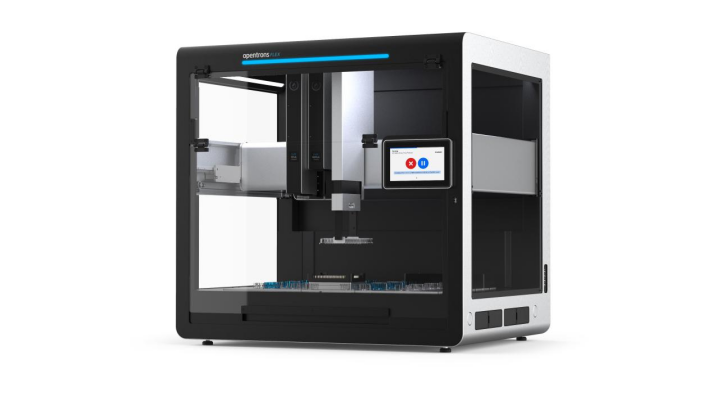

2. opentrons high-throughput pipetting workstation model opentrons high-throughput pipetting workstation product name is Opentrons Flex fully automatic pipetting workstation. Its main features are: 1. High flexibility (1) Pipette configuration: Flex workstation support Multiple pipette configurations, including any two Flex single-channel or 8-channel pipettes, or a single Flex 96-channel pipette. This flexibility allows the workstation to easily handle experiments of varying sizes and complexity. (2) Board space: The workstation deck has 12 main deck spaces and 4 additional board spaces for placing pipette tips, laboratory equipment and functional modules. 2. High-precision (1) Pipetting technology: Flex pipette adopts air displacement technology and is capable of high-precision pipetting of 1-1000 μL. The pipette is equipped with smart sensors with automatic calibration, real-time positioning and error detection functions to ensure the accuracy and stability of pipetting. (2) Pipetting accuracy: At 1 μL, the pipetting accuracy is 8% and the precision is 5%. This high-precision feature makes the Flex workstation capable of experiments that require extremely high pipetting accuracy. 3. Intelligent operation (1) Operation interface: The Flex workstation is equipped with a 7-inch LCD touch screen, which is made of anti-scratch and anti-damage LCD material. Users can complete experimental settings through a simple touch screen. The software system has intelligent graphic prompts, making the operation simple and easy to understand. (2) AI empowerment: Flex workstation supports AI-empowered laboratory automation. Through Opentrons' online protocol library and Python API open source, users can quickly develop protocols and implement intelligent automatic pipetting systems. 4. Broad compatibility (1) Consumable compatibility: Flex workstation is compatible with ANSI/SLAS standard well plates, as well as other commonly used laboratory equipment on the market, including conical reservoirs and test tubes up to 50 mL. (2) Equipment connectivity: Flex workstation supports multiple connection methods such as USB, Ethernet and Wi-Fi, making it easy to connect and integrate with other experimental equipment.

With the continuous advancement of science and technology and the growing demand for experiments, the market prospects of high-throughput pipetting workstations are very broad. In the future, high-throughput pipetting workstations will continue to develop towards higher precision, higher efficiency, and higher reliability. At the same time, they will be combined with cutting-edge technologies such as artificial intelligence and big data to achieve more intelligent laboratory automation solutions. .

The experienced service team and strong production support team provide customers with worry-free order services.