Flex应用专题 | 解锁蛋白质谱前处理自动化的无限潜能

Check the Details-

article · 2025Year3Moon9Day

清洗微孔板的具体步骤是什么

Read More -

article · 2025Year56Moon8Day

磁珠分选是什么

Read More -

Press release · 2025Year40Moon8Day

云端相约 | 邀您共同解锁蛋白质谱前处理自动化无限潜能

Read More

The liquid separation workstation, as a key piece of equipment in modern laboratories and industrial production, is gradually becoming an important tool for improving scientific research efficiency, ensuring product quality, and optimizing production processes with its excellent versatility and high automation characteristics. Its wide range of application fields and irreplaceable role not only promote the progress of science and technology, but also bring unprecedented convenience and benefits to all walks of life.

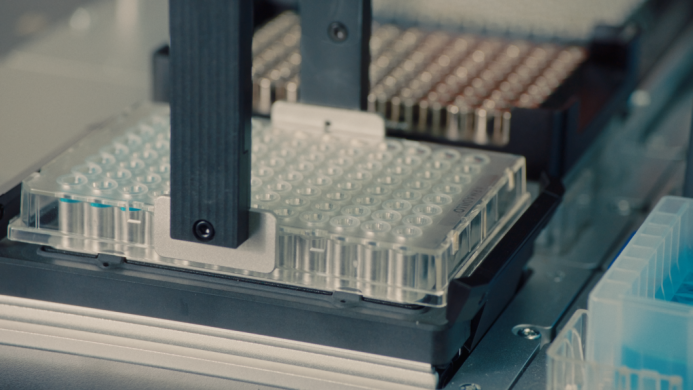

1. Improve production efficiency through automated operations: Through automation technology, the liquid separation workstation can automatically complete operations such as liquid absorption, distribution, mixing and packaging, significantly reducing the need for manual operations, thus improving production efficiency. Process multiple samples at the same time: The high-throughput liquid dispensing workstation can process multiple samples at the same time, realizing large-scale dispensing operations and further improving work efficiency. 2. Ensure precision and precise control: The liquid dispensing workstation adopts a high-precision pump and valve system, which can accurately control the volume and distribution ratio of liquid, ensuring the accuracy of the dispensing process. This is crucial for experiments or production processes that require precise proportions, such as drug screening, chemical synthesis, etc. Reduce errors: Automated operation reduces the interference of human factors, avoids errors caused by factors such as the operator's technical level and operating environment, and improves the reliability of experimental results. 3. Sealing technology to avoid cross-contamination: The liquid dispensing workstation adopts sealing technology, which effectively prevents cross-contamination between liquids during the dispensing process and ensures the purity and safety of the dispensing products. This is particularly important for the production of sensitive products such as pharmaceuticals and biological products. 4. Convenient experimental operation and easy operation: users only need to set the required liquid volume, distribution ratio and other parameters through the computer or touch screen, and the liquid dispensing workstation can automatically complete subsequent operations. This intelligent operation method makes experimental operations easier and faster. 5. Data recording and transmission Data recording: The liquid dispensing workstation can record and transmit data during the dispensing process, such as liquid volume, distribution ratio, time, etc., which provides convenience for product traceability and management. Data analysis: Through the analysis of data, users can understand the stability and efficiency of the dispensing process, and then optimize and improve the equipment. 6. Precise sampling for scientific research experiments: In scientific research fields such as biomedicine, chemistry, and molecular biology, liquid dispensing workstations can accurately and quickly complete liquid sampling and distribution, providing experimental personnel with efficient and accurate liquid processing solutions. This is critical for studies that require precise control of experimental conditions. High-throughput screening: In high-throughput experiments such as drug screening and gene sequencing, the liquid separation workstation can process a large number of samples at the same time, greatly shortening the experimental cycle and improving experimental efficiency. 7. Drug packaging in pharmaceutical production: During the drug production process, the dispensing workstation can pack drugs into different containers in accordance with strict requirements to ensure accurate dosage and packaging specifications, and comply with Good Manufacturing Practices (GMP). requirements. Aseptic operation: For pharmaceutical production processes that require aseptic operation, the dispensing workstation usually adopts an aseptic design to ensure a sterile environment during the dispensing process and avoid drug contamination. 8. Chemical production raw material distribution: In the chemical production process, the liquid separation workstation can accurately distribute various raw materials into the reaction kettle according to the formula requirements, ensuring the smooth progress of chemical reactions and stable product quality. Finished product filling: In the filling process of chemical finished products, the liquid separation workstation can realize automated filling, improve filling efficiency and filling accuracy, and reduce errors and pollution caused by manual operations. 9. Food safety and food packaging: In the food industry, liquid separation workstations can be used in the food packaging and packaging process to ensure food hygiene and safety. For example, liquid foods such as cooking oil and condiments are packaged into small packages for the convenience of consumers. Quality testing: During the food quality testing process, the liquid separation workstation can be used for sample sampling and distribution, providing accurate and reliable samples for subsequent testing and analysis. 10. Energy conservation, environmental protection and energy conservation: The liquid separation workstation adopts advanced control systems and energy-saving equipment, which can reduce energy consumption and production costs. For example, unnecessary energy consumption can be reduced by optimizing flow and pressure control during liquid distribution. Waste liquid treatment: The waste liquid generated during the liquid separation process can be processed and recycled through a specialized waste liquid treatment system to reduce waste liquid discharge and environmental pollution.

With the continuous advancement of science and technology and the growing demand for efficiency, precision, and automation in various industries, the technology of liquid dispensing workstations will continue to innovate and develop. In the future, we can look forward to the emergence of more intelligent and integrated liquid dispensing workstations. They will be able to better adapt to complex and changeable experimental and production environments, and provide scientific researchers and production personnel with more convenient, efficient, and reliable liquid processing. solution.

The experienced service team and strong production support team provide customers with worry-free order services.