-

article · 2025Year8Moon17Day

Opentrons Flex 使用中常见问题有哪些?

Read More -

article · 2025Year5Moon16Day

如何通过 Flex 提高蛋白质组学实验产能?

Read More -

article · 2025Year59Moon16Day

Opentrons Flex 的模块化设计是否有利于实验扩展?

Read More

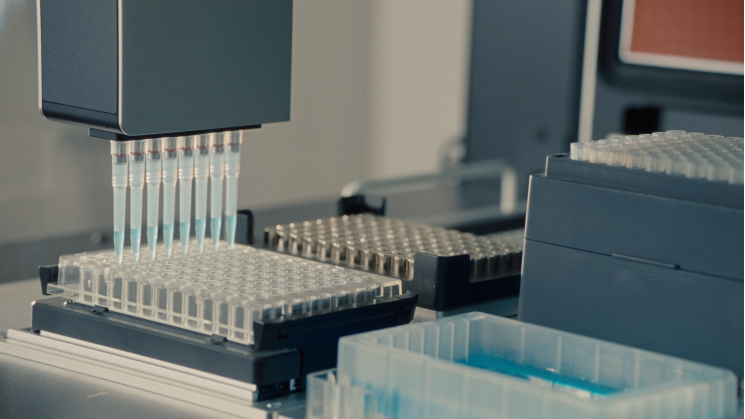

Dispensing workstations and pipetting workstations, as the two core equipment of laboratory automation, show clear differences in functional positioning, operating modes and application scenarios. The liquid separation workstation, as the name suggests, focuses on the precise separation and distribution of liquids. With its high accuracy and customized design, it shines in the fields of chemical synthesis and drug screening; while the pipetting workstation, with its comprehensive liquid processing Abilities—including moving, mixing, diluting, and more—play a vital role in disciplines as diverse as biochemistry, molecular biology, and more.

1. Definition and function 1. Liquid separation workstation: (1) Mainly used for the separation and distribution of liquids. It can accurately pack one or more liquids into different containers to achieve quantitative distribution of liquids. (2) Usually consists of a holder, a pipetting device and a container, through which the liquid is taken out of the container and distributed to other containers. (3) Suitable for experimental scenarios that require precise control of liquid volume and distribution, such as chemical synthesis, drug screening, etc. 2. Pipetting workstation: (1) Mainly used for operations such as moving, mixing, and diluting liquids. It can transfer a specific volume of liquid from one container to another and may involve mixing, diluting, etc. of the liquid. (2) It usually consists of a hydraulic conveying device, a weighing platform, a controller and a computer, and has the characteristics of programmability, high precision and high efficiency. (3) It is suitable for experimental scenarios that require precise control of liquid volume and operation in the fields of biochemistry, medicine, pharmacy, etc., such as PCR reactions, cell culture, etc.

2. Operation method 1. Liquid dispensing workstation: (1) The operation is relatively simple, and the liquid is mainly distributed quantitatively through the pipetting device. (2) The volume and speed of the dispensed liquid can be controlled by setting parameters. 2. Pipetting workstation: (1) The operation is more complex, involving multiple steps such as moving, mixing, and diluting liquids. (2) The operating parameters can be controlled by computer to achieve automated operation and improve experimental efficiency and accuracy.

3. Precision and accuracy 1. Liquid dispensing workstation: (1) Mainly focus on the quantitative distribution accuracy of liquid to ensure that the volume of liquid distributed into each container is accurate. 2. Pipetting workstation: (1) Pay attention not only to the accuracy of liquid transfer, but also to the accuracy and repeatability of liquid mixing, dilution and other operations during the entire experiment.

4. Overview of price range 1. Dispensing workstation: The price range is relatively wide, ranging from a few thousand yuan to hundreds of thousands of yuan. The specific price depends on the number of channels of the equipment (such as 8 channels, 96 channels, etc.), degree of automation, accuracy requirements, brand and other factors. For example, some basic 8-channel dispensing workstations may be more affordable, while high-precision, multi-functional 96-channel dispensing workstations may be more expensive. 2. Pipetting workstation: It also has a wide price range, but overall it may be more inclined to the mid-to-high-end market. The price of a pipetting workstation is also affected by factors such as equipment functionality, degree of automation, and brand. Some basic pipetting workstations may be moderately priced, while fully automatic, high-precision, and programmable pipetting workstations may be expensive, even hundreds of thousands or millions of yuan.

5. Price difference factors 1. Functional differences: Pipetting workstations usually have more complex operating functions, such as liquid mixing, dilution, distribution, etc., while liquid dispensing workstations focus more on quantitative distribution of liquids. Therefore, pipetting workstations may require more technical input and cost, resulting in higher prices. 2. Degree of automation: The higher the degree of automation, the higher the price. The fully automatic pipetting workstation can realize unattended operation, which greatly improves the efficiency and accuracy of experiments, but the corresponding cost will also increase. 3. Brand and quality: Well-known brands and high-quality equipment usually have better performance and longer service life, but the price is also relatively high. 4. Market supply and demand: Market supply and demand will also affect the price of equipment. If a certain model of equipment is in high demand but in short supply, the price may rise; otherwise, it may fall.

Dispensing workstations and pipetting workstations each show their unique charm and value on the stage of laboratory automation. With its precise liquid dispensing technology and customized solutions, the liquid dispensing workstation has become an indispensable assistant in the fields of chemistry, pharmaceuticals and other fields, ensuring the accuracy and repeatability of experimental results. The pipetting workstation, with its comprehensive liquid handling capabilities, high level of automation and wide applicability, has shined in many fields such as biological sciences and medical research, greatly improving experimental efficiency and the work experience of scientific researchers. .

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인