Flex应用专题 | 解锁蛋白质谱前处理自动化的无限潜能

Check the Details-

article · 2025Year3Moon9Day

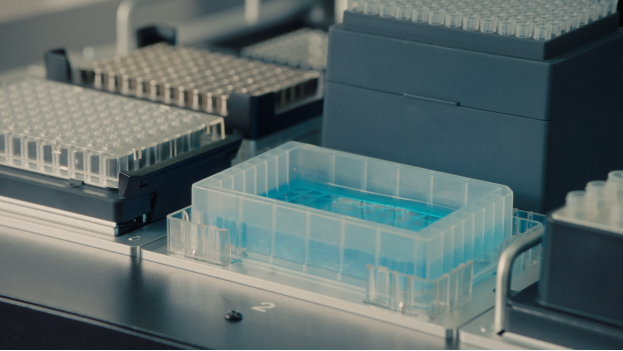

清洗微孔板的具体步骤是什么

Read More -

article · 2025Year56Moon8Day

磁珠分选是什么

Read More -

Press release · 2025Year40Moon8Day

云端相约 | 邀您共同解锁蛋白质谱前处理自动化无限潜能

Read More

The non-contact micro-liquid workstation, as a revolutionary technological breakthrough in the fields of modern life sciences, chemistry and materials science, is leading a new era of laboratory automation and precision operations. With its unique non-contact pipetting mechanism, this technology completely overturns the contamination risks and accuracy limitations caused by traditional contact pipetting methods, providing scientific researchers with an efficient, accurate and low-contamination trace liquid. Process the solution.

1. Features and advantages 1. High precision: The non-contact micro-liquid workstation can achieve precise distribution of liquids at picoliter (pL), nanoliter (nL) or even microliter (μL) levels, and pipetting accuracy is usually controlled at extremely low levels. Within the range, such as CV<1-3%, ensuring the accuracy of experimental results. 2. Non-contact operation: droplets are generated through pressure, sound waves, airflow or other non-contact mechanisms, which avoids direct contact between the liquid and the pipette or other parts, reducing the risk of cross-contamination while protecting the purity of the sample. and activity. 3. Multi-channel and modular design: Many non-contact micro-liquid workstations support multi-channel operation and can be matched with different dispensing modules as needed to achieve flexible liquid handling solutions. The modular design makes the equipment easy to upgrade and maintain to meet the needs of different experiments. 4. Automation and intelligence: Integrate advanced control systems, imaging quality control cameras and automatic calibration droplet volume modules to realize automatic control of the pipetting process and droplet detection and analysis functions. Intelligent design enables the equipment to automatically adjust parameters, optimize performance, and provide real-time feedback and alarm information. 5. Wide application: Non-contact trace liquid workstations are widely used in biological sciences, chemistry, medicine, materials science and other fields, especially in situations where high precision, high efficiency and low pollution liquid processing are required, such as chip R&D and production, microfluidics Control chip spotting, PCR reaction system setup, drug screening, mass spectrometry sample preparation, etc.

2. Representative products and technologies 1. BioFluidix BioSpot series: BioFluidix is a company focusing on the automation of micro-liquid processing. Its BioSpot series of workstations include BioSpot Arc and BioSpot Custom models. These workstations are capable of non-contact liquid dispensing at picoliter and nanoliter levels, and integrate imaging quality control cameras and modules that automatically calibrate droplet volumes to ensure the accuracy and reliability of the pipetting process. 2. Opentrons series: Although Opentrons may not be directly labeled as a non-contact micro-liquid workstation, its products such as fully automatic pipetting workstations and automatic pipetting robots may have similar functions and features and can meet the needs of micro-liquid processing. .

3. Disadvantages and limitations 1. High cost: Due to its advanced technology and complex structure, non-contact micro-liquid workstations often have high manufacturing costs and selling prices. This may limit its procurement and application by some laboratories or research institutions with limited budgets. 2. High technical threshold: This type of workstation usually requires operators to have certain professional knowledge and skills in order to operate and maintain the equipment correctly. For beginners or less skilled operators, a longer period of learning and training may be required. 3. Complex maintenance: The precision components and complex systems of the equipment require regular maintenance and upkeep to ensure their performance and stability. This may require specialized technicians, adding to the complexity and cost of maintenance. 4. Limited scope of application: Although the non-contact micro-liquid workstation is suitable for a variety of application scenarios, its high precision and special performance also make it not suitable for all types of liquid handling tasks. For certain liquids with special properties or specific experimental needs, other types of equipment or methods may be required.

The non-contact micro-liquid workstation is one of the indispensable tools in modern laboratories. It plays an important role in improving experimental efficiency, reducing contamination risks, and reducing costs. However, when selecting and using this type of equipment, factors such as the laboratory's specific needs, budget, technical level, and environmental conditions need to be fully considered.

The experienced service team and strong production support team provide customers with worry-free order services.