-

article · 2025Year0Moon8Day

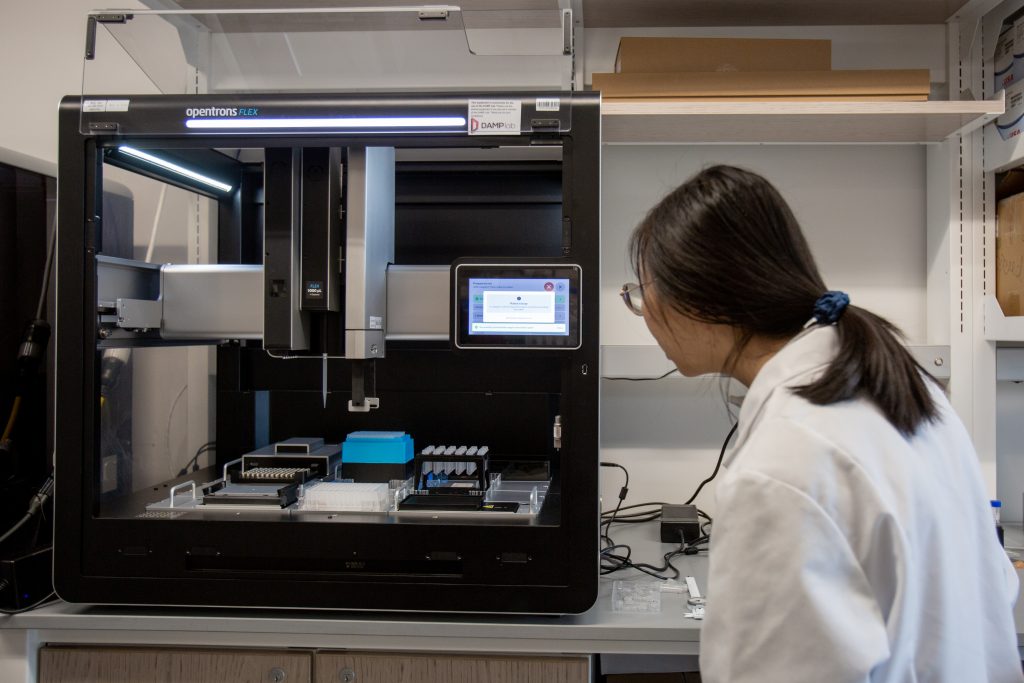

article · 2025Year0Moon8Day如何实现Flex平台对96/384孔板的高通量NGS任务?

Read More -

article · 2025Year55Moon8Day

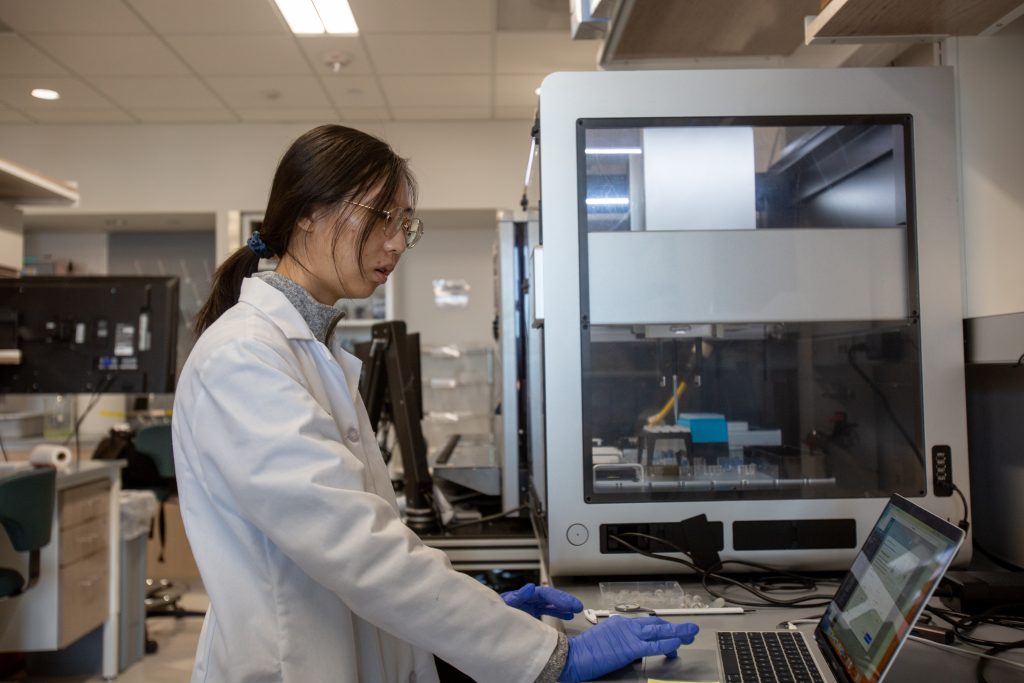

article · 2025Year55Moon8DayFlex系统在样本清洗与纯化步骤中的优势有哪些?

Read More -

article · 2025Year12Moon7Day

article · 2025Year12Moon7DayFlex高通量NGS平台适合中小实验室吗?

Read More

Automatic pipetting devices play a vital role in the laboratory, especially in high-throughput experiments. Their automation and high-precision features greatly improve experimental efficiency. However, ensuring the performance and accuracy of automatic pipetting devices is the key to successful experiments, and CV value (coefficient of variation) detection is an important means to evaluate these performance indicators.

1. What is CV value? CV value, the full name is Coefficient of Variation, is a dimensionless statistical indicator used to measure the degree of data dispersion. The calculation formula is the standard deviation (Standard Deviation) divided by the mean (Mean) and then multiplied by 100%, that is: CV = (mean/standard deviation) × 100%. The standard deviation reflects the deviation of the data points from the mean. degree, and the average is the average of multiple measurements. The CV value is expressed as a percentage. The smaller the value, the lower the variability of the data and the more accurate the pipetting process. In the application of automated pipetting devices, CV values are often used to evaluate the stability and consistency of the device across multiple dispensings of a specific liquid volume. For example, in pharmaceuticals, chemical analysis, and biological experiments, automatic pipetting devices often need to accurately dispense microliter-level liquids. By measuring the volume of liquid after multiple pipettes and calculating the CV value, the laboratory can determine whether the device meets the expected accuracy standards.

2. Why is CV value detection so important? In laboratory work, precise liquid dispensing is critical to the accuracy of experimental results. CV value testing of automatic pipetting devices helps laboratories ensure that equipment performance is maintained at optimal levels. This not only helps improve experimental reproducibility but also avoids data bias caused by equipment failure or lack of precision. In addition, CV value detection is also part of equipment maintenance and calibration. By regularly testing CV values, laboratory technicians can promptly detect and correct problems that may affect equipment performance, such as wear or improper calibration of pipetting tips. This helps extend the life of the equipment and reduces maintenance costs while ensuring efficient laboratory work.

3. How to detect CV value? CV value detection usually includes the following steps: 1. Prepare samples and equipment: select an appropriate liquid sample and set the corresponding pipetting volume according to the specifications of the pipetting device. Make sure the equipment is properly calibrated and in working order. 2. Multiple measurements: Use an automatic pipetting device to perform multiple liquid distributions under the same conditions, usually no less than 10 times, to ensure the reliability of the data. 3. Record data: measure the liquid volume after each dispensing and record the results of each measurement. 4. Calculate the CV value: Based on the recorded data, calculate the mean and standard deviation, and then use the formula to calculate the CV value. 5. Analyze the results: Compare the calculated CV value with the accuracy standard provided by the equipment manufacturer. If the CV value is below the specified limit, the device's performance meets the requirements; if the CV value exceeds the limit, the device may need to be adjusted or repaired.

4. How to optimize the CV value of automatic pipetting devices? 1. Regular calibration: Ensure that the equipment is calibrated regularly to maintain its accuracy. 2. Equipment maintenance: timely replace worn pipetting heads or other key components to reduce errors. 3. Operation training: Provide adequate training for operators to ensure that they can use the equipment correctly and reduce the impact of human factors on the CV value. 4. Environmental control: Control the temperature, humidity and other environmental conditions in the laboratory to avoid adverse effects on pipetting accuracy.

CV value detection of automatic pipetting devices is an important step to ensure the accuracy of laboratory experimental results. Through effective CV value detection, laboratories can monitor and optimize equipment performance, thereby improving the success rate of experiments and the reliability of data. Regular CV value testing and maintenance can not only extend the service life of equipment, but also reduce laboratory operating costs and ensure that laboratories maintain a leading position in the fierce scientific research competition.

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인