-

article · 2026Year2Moon5Day

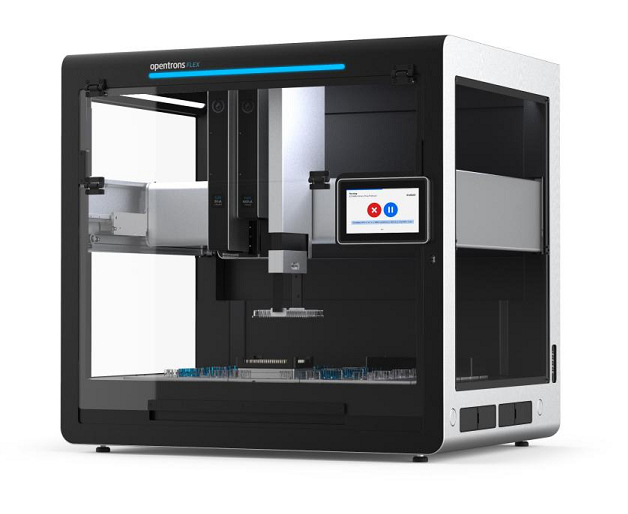

Opentrons Flex 高通量 NGS 工作站安装与调试全流程

Read More -

article · 2026Year57Moon5Day

实验室如何利用 Opentrons Flex 实现高质量数据输出

Read More -

article · 2026Year57Moon4Day

Opentrons Flex vs 其他自动化 NGS 工作站对比评测

Read More

The sample pretreatment workstation is an important equipment in the laboratory for preprocessing biological, chemical or environmental samples. This workstation integrates a variety of functional modules designed to improve the efficiency and accuracy of sample preprocessing, thereby providing high-quality samples for subsequent analysis or experiments.

1. Sample pre-processing workflow

1. Sample collection

2. Sample reception and registration

3. Sample classification and grouping

4. Sample pre-processing

5. Sample packaging and storage

6. Quality control and records

7. Analysis and detection

2. Opentrons automated pipetting workstations and liquid handling systems can achieve sample preprocessing 1. High precision and accuracy. Opentrons automated pipetting workstations and liquid handling systems have high-precision and accurate pipetting functions. This is achieved through advanced electronic pipettes or multi-channel pipettes, which can ensure the accuracy of liquid distribution and transfer during sample pre-processing, thereby avoiding errors that may be caused by human operations. This high precision and accuracy is crucial for sample preprocessing because it directly affects the reliability and accuracy of subsequent experimental results. 2. Versatility and flexibility. Opentrons' automation platform is not limited to a single pipetting operation, but can also perform a variety of complex operations such as mixing, dispensing, dilution, and shaking. These functions are essential in the sample preprocessing process and can meet the needs of different experimental scenarios. In addition, the opentrons workstation also has good compatibility and scalability, and can support multiple types of consumables and experimental equipment, allowing users to select and match according to their own experimental needs to achieve personalized sample preprocessing solutions. 3. Programming control and automation Opentrons’ automated pipetting workstations and liquid handling systems realize automated operations through programming control. Users can write corresponding programs to control the operation of the workstation according to their own experimental needs. This automated operation not only greatly improves the efficiency of sample pre-processing, but also reduces errors and uncertainties that may be caused by manual operations. At the same time, automated operations also make the experimental process more standardized and repeatable, helping to improve the stability and reliability of experimental results. 4. Wide range of application fields The opentrons automation platform is widely used in many fields such as microbiology, molecular biology, and biochemistry. Sample pre-processing processes in these fields are often complex and tedious, requiring high-precision operations and strict control. opentrons' automation platform is capable of these tasks and provides scientific researchers with efficient and accurate sample preprocessing solutions. 5. User-friendly design and operation interface Opentrons automated pipetting workstations and liquid handling systems are usually equipped with user-friendly design and operation interface. This makes it easy for users to get started and master operating skills quickly. At the same time, some advanced models are also equipped with interactive devices such as touch screens and smart displays, allowing users to intuitively monitor the experimental process and adjust experimental parameters.

The main reasons why opentrons automated pipetting workstations and liquid handling systems enable sample preparation include high precision and accuracy, versatility and flexibility, programmable control and automation, a wide range of application fields, and user-friendly design and operating interface. These factors together make opentrons' automation platform an important tool for efficient and accurate sample preparation in the laboratory.

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인