Flex应用专题 | 解锁蛋白质谱前处理自动化的无限潜能

Check the Details-

article · 2025Year27Moon6Day

微孔板振荡器在工作站中的应用

Read More -

article · 2025Year22Moon6Day

全自动移液工作站哪个品牌好

Read More -

article · 2025Year21Moon4Day

DNA半保留复制实验有哪些注意事项

Read More

Tech ambition can be gauged by the analogies founders like to throw away in interviews. The Uber of X, the Amazon of Y, it’s all very impressive if this startup succeeds. But Will Canine, the organizing force behind OpenTrons, has higher goals: "Today's biology lab automation is what computers were in the 1960s—a mainframe with punch cards, run by lab technicians. We are PCs."

For anyone with an exciting futuristic mindset, this will evoke all kinds of wild techno-utopian fantasies. When you see Opentrons' open source robot OT.One on Kickstarter, you think: Finally, a MakerBot made for life itself. Donate enough to the campaign (hopefully they'll actually pull it off) and you'll print glow-in-the-dark fish that smell like strawberries and instantly secrete life-saving cancer drugs.

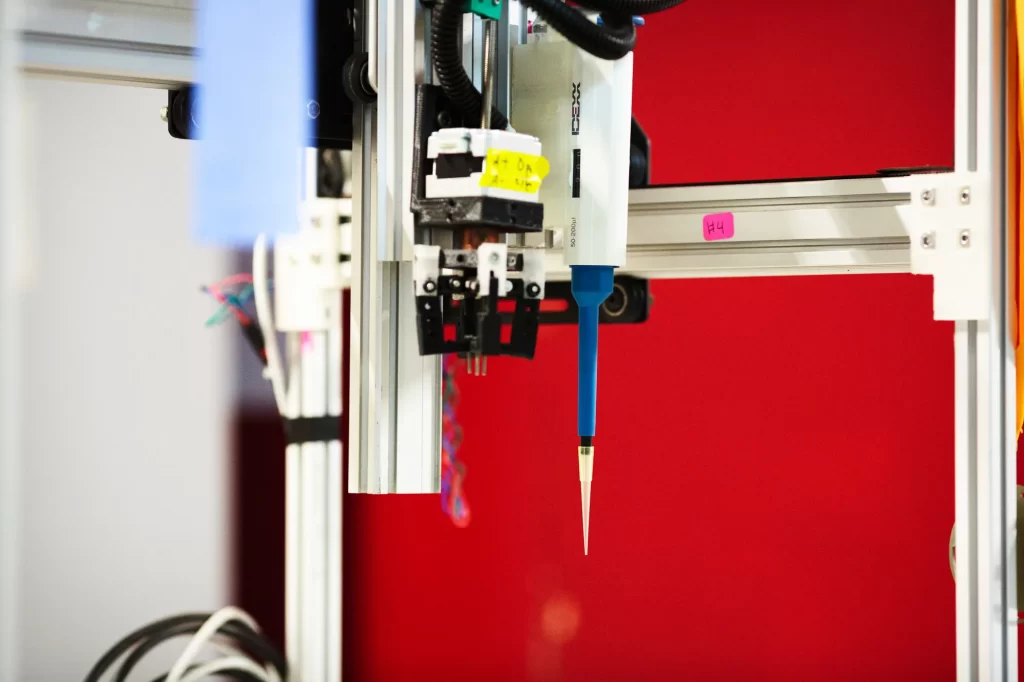

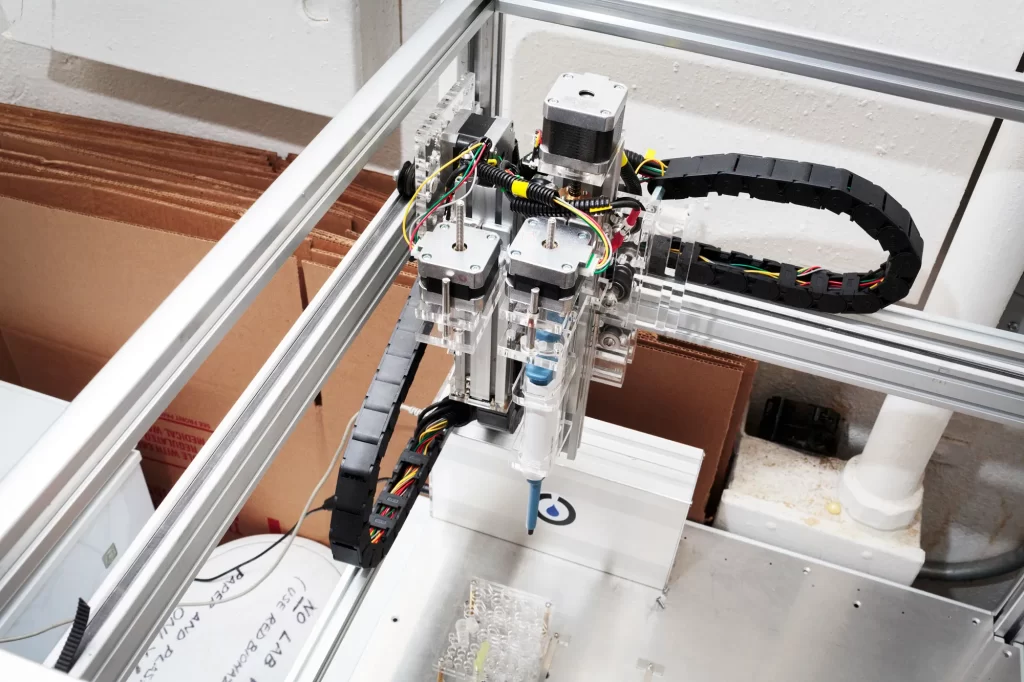

But what this actually means - a PC revolution in biology - is a little more complex, but also more practical. Technically speaking, OT.One is a liquid handling robot. Rather than squeezing oozing synthetic life onto a plate, it will automate the tedious work that makes up most biological research. Canine's mainframe analogy is spot on, as existing biolab robots cost around $50,000 (quickly rising into six figures) at their most basic, require weeks of training to use properly, are definitely not open source, and Usually dedicated to only one laboratory task.

After tinkering with MakerBots for a while, Canine decided to sign up for an introductory synthetic biology course at Genspace, a DIY biolab in Brooklyn. He had been taking biology courses in high school, but was dropped when he entered the junior laboratory class during his freshman year of college. There, back in the humid working environment, he had to face an uncomfortable truth: his pipetting skills were terrible.

“I was like, ‘Damn, I didn’t get a PhD in microbiology, so I don’t have any lab skills,’” Kanion said. But, he thought, who needs technology when you have robots?

He contacted two technicians on the DIY Bio list who had more experience than he did, Nick Wagner (a software guy) and Chiu Chau (a robotics technician with decades of biorobotics experience). OpenTrons was born. They built the robot's brain around an open-source Raspberry Pi board, and for the robot's precision-controlled arms, they used an open-source Smoothieboard. OT.One is designed to use a standard manual pipette, replacing the unfortunate postdoc's tired thumb with a little robotic plunger, and it's equipped with a webcam so researchers can make sure the protocol is running smoothly (and possibly figure out what went wrong, If they let it run all night).

Canine, Wagner, and Chau were accepted into the Shenzhen-based hardware accelerator HAXLR8R last spring, shortly after the prototype was completed and before Canine's ITP paper was published. The team sets off for China. They lived there over the summer working on building the OT.One into a product that could be mass-produced, and when they returned to the United States, they immediately launched a Kickstarter campaign. They haven't had time to run the tests needed to generate reliable data on the bot's error rate or accuracy, but that didn't stop nearly 200 people from donating more than $75,000 to the campaign.

Saving graduate students from carpal tunnel and allowing incompetent DIY biologists to conduct experiments without years of pipette training is all well and good, but Canine's vision for OpenTrons goes further. Cheap open source automation brings standardization and spreads in every lab that invests $3000 (or just $2000, if you go to Kickstarter) for OT.One. According to some surveys, the proportion of experimental results that can actually be reproduced by another laboratory following the methods proposed in published studies is surprisingly low—say, ten percent lower. It's unclear why this problem occurs, but variations in conditions, experimental protocols, and even pipetting techniques between laboratories are uncontrolled variables.

Canine believes that widespread automation, combined with the open-source ethos of makers, DIYers and the Occupy movement, may be able to increase that ratio. Solving this part of the problem will require more than just a cheap robot.

OT.One is controlled by a browser-based interface called Mix.Bio, which allows users to drag and drop different commands, liquids, and biological components into protocols that OT.One then runs. Synthetic biology has always used DNA as a metaphor for programming, and Mix.Bio puts a user-friendly GUI on top of it. Mix.Bio also allows users to easily share and download protocols, which brings the entire system back to the MakerBot concept.

"Our whole goal is to be a digital fabrication machine for life sciences labs," Canine said. "You can email a friend a file, make sure you have the right filament or material on the bed, and hit run."

The OpenTrons system still relies on a lot of manual biology work—the material in the MakerBot bed is a pile of plastic; the material in the OT.One bed is a complex and fragile assemblage of biological building blocks suspended in liquid, but in an ideal world , this automation will allow for fast, trustworthy distributed experiments. Hundreds of OpenTrons systems around the world can run the same experiment simultaneously, producing orders of magnitude more data in a relatively short period of time than any one laboratory could produce alone. As systems are planned to be added, such as the centrifuge that Canine estimates may be available next summer, these sharable protocols will be able to replicate increasingly complex experiments.

Ultimately, the PC analogy is a bit unsatisfying to people accustomed to thinking in terms of Moore's Law. Biological processes require more time than computers. The manipulated organism takes time to grow, but more importantly, using the entire DNA as a metaphor for a programming language is fundamentally misleading. We can't hack directly into the command line of our lives yet, we can only try to fiddle with it over a weak connection and hope that the intended changes will be completed without breaking the entire system. Even then, it will take a few days (and a lot of pipetting) to see if it has any effect. One of the biggest success stories in synthetic biology comes from the University of California, Berkeley, where researchers successfully genetically modified yeast to produce an anti-malarial drug called artemisinin. Jay Keasling, the lead scientist on the work, estimates the project will require 150 man-years of work to complete.

Given the relative immense complexity and slow pace, it seems a bit silly to ask Canine about the dangers of someone making a homemade biological version of a 3D-printed gun, some kind of super virus, or a new antibiotic-resistant plague, but he takes the question seriously. "We are right to be afraid of biotechnology because it is very, very powerful stuff," he said. “But I think the problem is not the technology, it’s the people who have the technology, and so far technology has been used primarily to reinforce toxic practices and maintain strangleholds on things like agricultural production.”

Returning to his first analogy, he continued: “Computers were originally developed to drop bombs, and not everyone started out making GIFs on them and smiling at the amazing stuff. But we’re trying to do that. One thing is to enable people to use biotech innovation to make products that are not constrained by profit-seeking constraints. The way to make better biotech is not to limit who can actually make it, but to make it available to everyone."

All photos by Andrew White/Re:form

The experienced service team and strong production support team provide customers with worry-free order services.