-

article · 2025Year56Moon27Day

Flex 移液器如何满足不同实验需求?

Read More -

article · 2025Year53Moon27Day

模块化移液器带来的实验室灵活性提升

Read More -

article · 2025Year37Moon26Day

高通量实验必备:Flex 移液器全面解析

Read More

1. Preparation stage

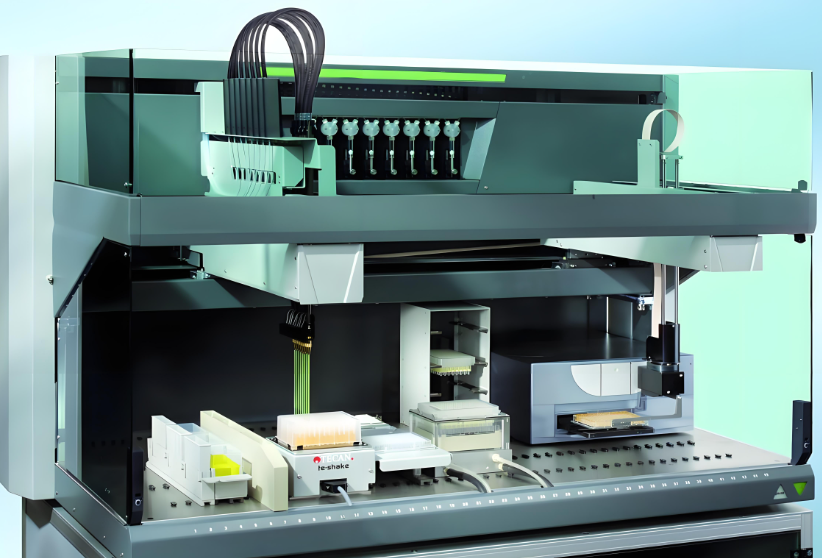

1. Program setting: The operator sets the liquid treatment program and parameters according to the experimental needs through a controller or an external tablet computer and other smart devices. These parameters may include pipetting volume, pipetting speed, pipetting mode (such as basic pipetting, continuous dispensing, gradient dilution, etc.), target position, etc.

2. Installation of consumables: Install the liquid storage device (such as reagent tank, microplate, etc.) and waste liquid collection device on the workstation, and ensure that they are correctly connected to the pipetting module. At the same time, check whether the pipetting head is clean and not damaged, and prepare enough pipetting heads for subsequent use.

2. Automated operation stage

1. Automatic attachment and removal of pipette heads: The pipetting module automatically assembles pipette heads according to program requirements. Before each pipetting operation, the pipetting head will be checked to ensure that the pipetting head is installed correctly to ensure smooth operation.

2. Liquid aspiration: Under the command of the control system, the pipetting head accurately absorbs the specified amount of liquid sample or reagent from the liquid storage device. This step is usually accomplished with negative or positive pressure, depending on the design of the device.

3. Liquid distribution: The pipetting head distributes the sucked liquid to the target location according to the program requirements. This may include specific well positions on microplates, reaction systems on PCR plates, etc. During the dispensing process, the pipetting head moves according to a preset path and speed to ensure accurate distribution of liquid.

4. Mixing and dilution (if applicable): For liquid samples that need to be mixed or diluted, the liquid handling workstation can also perform corresponding operations. This is usually achieved through specific mixing modules or dilution modules, ensuring accuracy and consistency in liquid handling.

5. Waste liquid treatment: The treated waste liquid is collected into the waste liquid collection device. During the operation of the workstation, the waste liquid collection device will continuously receive waste liquid from the pipetting module until the end of the experiment.

3. Data processing and finalization stage

1. Data recording: The data processing system records experimental data and results in real time. These data include key parameters such as pipetting volume, pipetting time, and pipetting speed, as well as any abnormalities during the experiment.

2. Result analysis: After the experiment, the operator can analyze the experimental data through the data processing system. This helps evaluate experimental results, optimize experimental conditions, and improve experimental methods.

3. Equipment cleaning and maintenance: After completing the experiment, the liquid handling workstation needs to be cleaned and maintained. This includes cleaning components such as pipetting heads, liquid storage devices and waste collection devices, as well as checking the operating status and performance indicators of the equipment.

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인