Flex应用专题 | 解锁蛋白质谱前处理自动化的无限潜能

Check the Details-

article · 2025Year3Moon9Day

清洗微孔板的具体步骤是什么

Read More -

article · 2025Year56Moon8Day

磁珠分选是什么

Read More -

Press release · 2025Year40Moon8Day

云端相约 | 邀您共同解锁蛋白质谱前处理自动化无限潜能

Read More

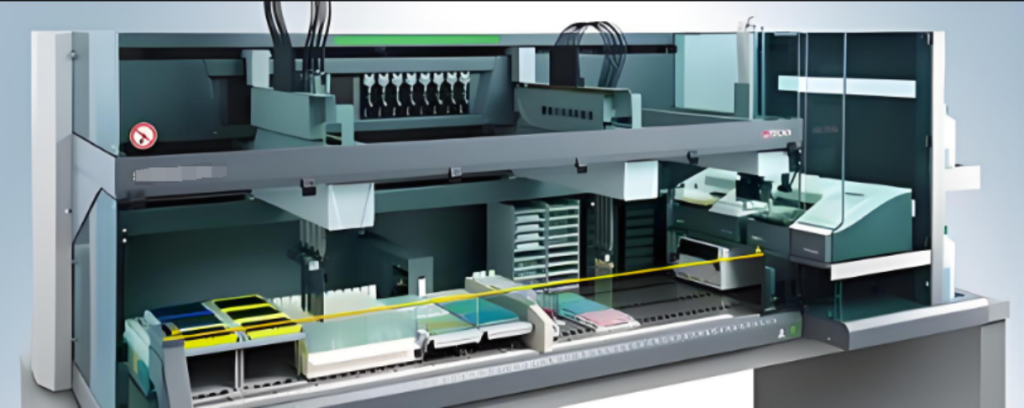

The 96-channel pipetting workstation is an accurate and economical 96-channel automatic pipetting workstation that enables fast and accurate pipetting by filling plates, adding reagents or transferring samples in one step. The user-friendly design and user-friendly operation interface simplify the tedious and repetitive microplate sampling operations, reduce errors, make the experimental process safer, and the data results more reliable.

The 96-channel pipetting workstation module adopts air displacement technology. The system is equipped with a 96-channel air jet pump pipetting device. The pipetting is accurate and reliable. It can automatically move up and down the entire box of nozzles without assistance. Liquid handling range: 0.5µL ~ 1000µL, three Range: 0.5-30µL range provides you with small volume pipetting; 2.5-200µL range will be your workhorse; 100-1000µ A range of L is available for bulk reagent packaging.

High degree of automation: the pipetting process can be edited, started with one click, no one operates during the whole process, pipetting speed control can control better immersion depth, the suction nozzle has accurate air holes, high consistency among 96 channels, and 384-well pipetting only takes 4 8-channel gradient dilution (gradient dilution per column) can be performed to avoid manual operation errors.

Product features of 96-channel pipetting workstation:

The patented technology of this utility model provides a 96-channel pipetting workstation, which includes a moving mechanism bracket and a moving mechanism (including a moving liquid mechanism). The moving liquid mechanism includes a moving base, and the moving base is provided with a startable movable rod. The moving rod driving mechanism has a straight rail fixed seat; a moving fluid is also installed at the bottom of the moving rod. The patented technology of this utility model - the 96-channel pipetting workstation can greatly buffer the impact and vibration during operation. The transmission noise is small and the transmission is stable, making the workstation's mobile LALAD mechanism more flexible in operation, and the moving head can use more plate positions.

The experienced service team and strong production support team provide customers with worry-free order services.