Co-founder of biotech company Parhelia Bio Nikolay Samusik and Yury Goltsev developed (and patented) a plug-in module. This module turns any automated pipetting platform into an automated stainer for microscopy samples. Now, they use the Opentrons OT-2 automated pipetting platform and Opentrons Python protocol API to automate staining protocols such as routine immunofluorescence, Akoya's CODEX, and antigen retrieval on IHC and FFPE samples.

Opentrons: How did you come up with the idea of having the Parhelia device automatically stain slides using a liquid handler?

Nikolay Samusik: The idea and need for the Parhelia PAR2 device grew out of research we were doing in Garry Nolan's lab at Stanford University, where we were working on an ultra-high multiplex discovery tissue staining protocol called CODEX. CODEX and its clinical-grade high-throughput partner OPAL are currently distributed by another company we founded, Akoya Biosciences.

Yury Goltsev: In the process of developing CODEX, OPAL and other advanced tissue staining methods, we learned that complex protocols like RNA FISH and multiplex IHC, although easy for us developers, But it is difficult for users and the learning curve can be quite high. The multi-step process takes a lot of time, the entire procedure can easily take more than a day depending on the antibody/probe incubation time, and manual pipetting errors can be difficult to avoid for both novice students and experienced technicians. We realized we needed a special piece of equipment to automate our staining, but most of the automation on the market started at over $150,000, which our lab couldn't afford. We also couldn't find an automated stainer that could handle coverslips - the flat support medium used in CODEX.

Opentrons: Why is tissue staining so difficult?

Yury Goltsev: Because in the tissue staining process, multi-step processing and learning new staining protocols require a lot of practice and effort. To run investigative projects that involve processing large amounts of tissue samples, you must have a dedicated technician (or even a team of technicians) diligently following all the steps. A postdoc working on complex multicolor stains will spend most of their time at the bench and will have no time to read and analyze the data. This results in a lot of unnecessary manual labor and leads to questions about whether experiments are reproducible, which we believe can only be solved through effective automation.

Opentrons: How did you integrate the OT-2 into your lab?

Yury Goltsev: Instead of spending $250,000 on a fully automatic dyeing machine on the market, we bought a $200 3D printer that can basically do the same job and achieve XYZ tool positioning of automation. But when we saw the OT-2, we decided it was the perfect choice for us: it had the features we needed, looked great, was cost-effective, and we could integrate it with our equipment.

Opentrons: Did you look into other automated liquid handling equipment before using the OT-2?

Nikolay Samusik: We don’t know much about it, but we have programming knowledge. The OT-2 platform is uniquely open source, so we can use Python to easily interact and develop with OT-2.

Opentrons: How is it getting your OT-2 up and running?

Yury Goltsev: For us, the OT-2 operating experience has been very good. The advantage of OT-2 is that it supports at least three ways to interact with it, such as Jupyter notebooks, SSH shell and the Opentrons Python API . And what I find amazing is that the protocol runs on the device, not on the computer, so if the computer disconnects from the robot or something goes wrong, the device will still continue to run the protocol.

Opentrons: Did you encounter any difficulties setting up your OT-2?

Yury Goltsev: We found that the initial calibration process may be a little difficult depending on the firmware version guidelines of the Opentrons APP. But Opentrons' customer support team has always responded quickly to help us solve our problems. Overall we think this is a great device, runs very smoothly and we love it.

Opentrons: Please share with us about automated FFPE antigen retrieval using OT-2.

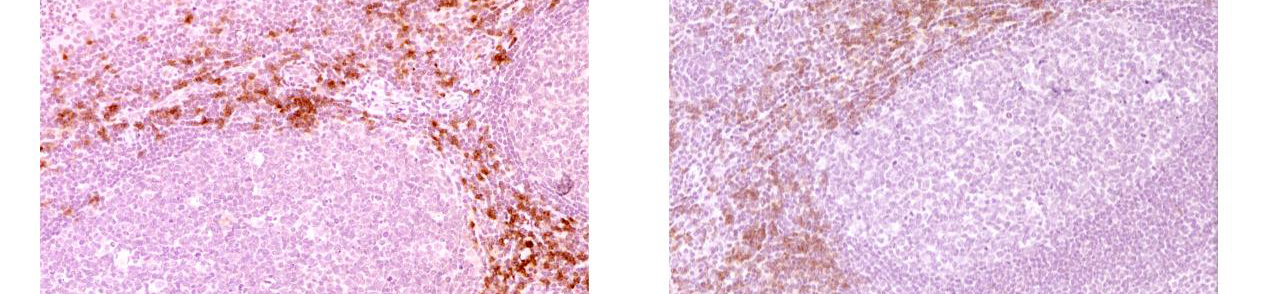

Nikolay Samusik: One of our biggest achievements so far is automating FFPE antigen retrieval (an epitope demasking step that requires precise high-temperature processing) in IHC protocols. We achieved this by using the Parhelia PAR2 device with the Opentrons temperature module. There are few other staining machines on the market that can perform both heat treatment and staining, and large instrument vendors will charge more for equipment with the ability to perform both antigen retrieval and antibody staining in a single instrument. The OT-2 is different, it allows us to run temperature-controlled experiments with an onboard temperature module and opens up a whole new range of protocols for us, now we can do everything a high-end automated dyeing machine can do.

Opentrons: Tell us about your experience using the OT-2 for a range of manipulations and treatments of experimental fluids.

Yury Goltsev: Our equipment is very compact and easy to carry, so we are able to put everything into the 96-well plate position (SBS plate position) and make it compatible with all automated pipetting equipment . Secondly, we want all liquids to be kept inside the box as this helps maintain humidity and prevents biohazard leaks. For hazardous samples, they are also completely sealable using our equipment, you can do whatever you want and discard the box safely when needed. We believe this is particularly important when dealing with highly contagious diseases such as COVID-19.

Opentrons: What are your current visions for market expansion?

Yury Goltsev: We are very optimistic about the market in developing countries because our products are much cheaper than other automatic dyeing machines, in fact 20 times cheaper. This is a great option for Africa or Latin America, or anywhere with a tight research budget.

Opentrons: Is there anything else you would like to share with everyone about using OT-2?

Nikolay Samusik: We were hugely inspired by OT-2 and Opentrons. This company is disrupting the liquid handling market and is aligned with how we want to disrupt the automated dyeing market. Most laboratories do not have automated pipetting equipment precisely because their budgets cannot afford it and most automated pipetting equipment is complex and difficult to use. But after using OT-2, our actual experience tells us that OT-2 is different from traditional automated pipetting equipment.

Yury Goltsev: We have a big plan. Frankly, our equipment is much more than a slide stainer. We plan to use it in conjunction with a microscope. For example, coverslips are used in a variety of research contexts beyond staining tissue. Our equipment can automatically process proteins, DNA or chemicals arrayed on glass. You can put in any sample that requires laminar fluid exchange and let our equipment, along with the OT-2, handle it by creating a laminar flow situation for the system. Opentrons opens up endless possibilities for us.

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인