-

article · 2026Year31Moon7Day

Flex蛋白质组学工作站如何简化蛋白质样品处理与分析流程?

Read More -

article · 2026Year56Moon6Day

Flex蛋白质组学工作站的自动化功能,如何提升定量精度?

Read More -

article · 2026Year53Moon5Day

Flex蛋白质组学工作站的磁力模块:提升蛋白质纯化效率

Read More

The automatic dispensing workstation peristaltic pump, as an outstanding representative of modern laboratory automation and precision control technology, has demonstrated extraordinary performance in scientific research, pharmaceuticals, chemical analysis, environmental monitoring and other fields with its unique working principle and excellent performance. application value. This core equipment not only integrates high-precision flow control technology, but also integrates advanced automated operation concepts to provide efficient and reliable solutions for complex and changeable liquid handling tasks.

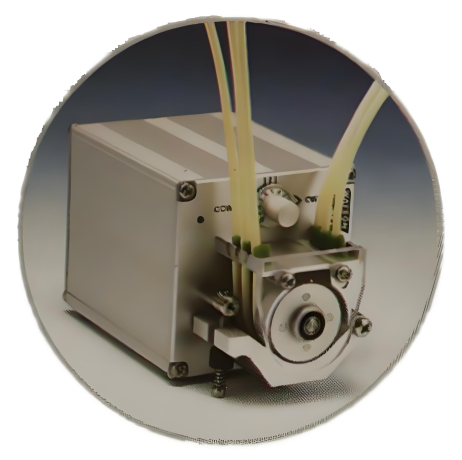

1. Working principle 1. Structure: (1) The peristaltic pump is the core component of the automatic liquid dispensing workstation. It usually consists of a driver, a pump head and a hose. The pump head contains rollers or rotors that squeeze the hose. (2) The hose serves as a liquid transmission channel, with one end connected to the feed port and the other end connected to the discharge port or receiving container. 2. Working cycle: (1) When the peristaltic pump starts to work, the driver drives the roller or rotor to roll along the length of the hose. (2) The roller or rotor will periodically squeeze the hose during the rolling process, making the hose cross-section smaller and closed, forming a continuous "pillow" shaped fluid area. During this process, the liquid in the hose will be squeezed, forming a peristaltic wave inside the hose. (3) The peristaltic wave starts from the feed port and moves toward the discharge port as the roller or rotor continues to roll. In this process, the liquid is pushed and transported to the discharge port or receiving container. 3. Flow control: (1) The flow control of the peristaltic pump is mainly achieved by adjusting the speed of the roller or rotor and the length of the squeeze hose. The faster the rotation speed, the higher the extrusion frequency and the greater the flow rate; the longer the extrusion length, the greater the amount of liquid transported per extrusion, thus affecting the overall flow rate. (2) In an automatic dispensing workstation, the peristaltic pump is usually connected to the control system to accurately control the flow rate and delivery time through preset programs or user-input parameters.

2. Features and advantages 1. High precision: Due to its unique working principle, peristaltic pumps can achieve precise liquid control without pollution and leakage, which is particularly important for experiments and industrial production that require high-precision liquid separation. 2. Versatility: The peristaltic pump of the automatic dispensing workstation is not limited to a single dispensing function, but can also be customized and upgraded according to needs to meet different experimental and production needs. 3. Easy to operate: Modern automatic dispensing workstation peristaltic pumps are usually equipped with touch screen and button operation interface, making the operation more intuitive and convenient. 4. Stability: The peristaltic pump has a relatively simple structure and is easy to maintain. Because it has a small stirring and shearing effect on the liquid, it can maintain the integrity of the liquid, thus improving the stability of liquid separation. 5. Wide applicability: Peristaltic pumps are suitable for transporting high-viscosity, corrosive or volatile liquids, so they are widely used in many fields such as chemistry, medical care, food, and pharmaceuticals.

3. Application fields 1. Biomedical field: In the process of drug research and development, clinical trials, biological product preparation, etc., the peristaltic pump of the automatic liquid separation workstation can be used for liquids in experimental operations such as high-performance liquid chromatography analysis, protein separation and purification, and cell culture. Dispensing and injecting samples. 2. Chemical analysis field: In chemical analysis, the automatic liquid separation workstation peristaltic pump can be used for sample preprocessing and liquid sampling, automatically completing sample dilution, mixing, extraction and other operations to improve experimental efficiency and accuracy. 3. Environmental monitoring field: In environmental monitoring, the automatic liquid separation workstation peristaltic pump can be used to collect and process water samples, soil and other environmental samples, automatically completing sample collection, extraction, purification and other operations, improving monitoring efficiency and accuracy .

After in-depth discussion of the many advantages and applications of peristaltic pumps in automatic dispensing workstations, we can easily find that this equipment has become an indispensable part of modern laboratories and industrial production. It not only represents the latest progress in liquid processing technology, but also is a microcosm of the era of automation and intelligence, showing the infinite possibilities of the deep integration of technology and industry.

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인