Flex应用专题 | 解锁蛋白质谱前处理自动化的无限潜能

Check the Details-

article · 2025Year3Moon9Day

清洗微孔板的具体步骤是什么

Read More -

article · 2025Year56Moon8Day

磁珠分选是什么

Read More -

Press release · 2025Year40Moon8Day

云端相约 | 邀您共同解锁蛋白质谱前处理自动化无限潜能

Read More

The micro-dispensing workstation can automatically complete liquid aspiration, distribution and transfer operations according to preset procedures through precise mechanical arms, pipetting systems and control systems. These operations can be performed between different containers (such as Petri dishes, centrifuge tubes, PCR plates, etc.) for efficient sample processing and preparation.

1. Working principle of micro-dispensing workstation 1. Mechanical control Micro-dispensing workstation is usually equipped with precision mechanical arms or mechanical transmission systems. These systems achieve precise position control and movement through driving components such as motors, stepper motors or servo motors. control. The robotic arm or transmission system can move in three-dimensional space according to a preset path and speed, thereby accurately positioning it above the target container to absorb, distribute and transfer liquids. 2. Liquid handling technology (1) Pipetting method: The microdispensing workstation adopts a variety of pipetting methods, the most common of which are peristaltic pump and syringe methods. Peristaltic pumps push liquid flow by compressing hoses and are suitable for handling liquids with higher viscosity or containing particles. The syringe method controls the inhalation and discharge of liquid by pushing the piston or push rod. It has the advantages of controllable liquid dispensing speed and simple implementation principle. (2) High-precision control: Whether it is peristaltic pump or syringe method, the micro-dispensing workstation achieves high-precision distribution of liquid through a precise control system. The control system can precisely control the rotation angle of the motor or the advancement stroke of the push rod to control the amount of liquid absorbed and dispensed. At the same time, some high-end equipment also adopts a closed-loop control system to further improve the accuracy of distribution by monitoring the actual amount of liquid dispensed in real time and making feedback adjustments. 3. Automated program control (1) Preset program: Users can preset a series of operating programs on the microdispensing workstation according to experimental needs. These procedures include the amount of liquid absorbed, the amount of liquid dispensed, the location of the liquid dispensed, and the sequence of operations. Preset programs can be stored in the device's memory so they can be recalled at any time when needed. (2) Automated execution: During the experiment, the microdispensing workstation will automatically perform various operations according to the preset program. The robotic arm or transmission system will move according to the path and speed indicated by the program, while the liquid handling system will absorb, distribute and transfer the liquid according to the parameters set by the program. The entire process does not require manual intervention, greatly improving the efficiency and accuracy of the experiment. 4. Intelligent functions Some high-end micro-dispensing workstations also have intelligent functions, such as automatic calibration, automatic container identification, automatic parameter adjustment, etc. These features can further reduce human error and improve the reliability and stability of experiments.

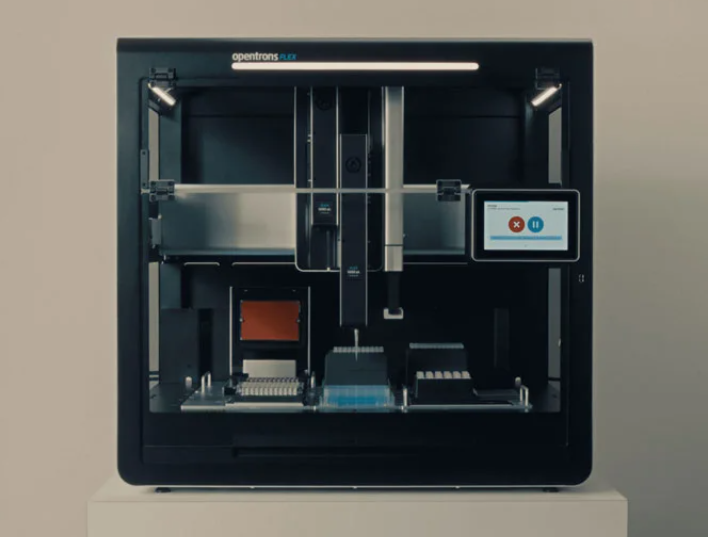

2. Brand introduction Opentrons has launched workstations with micro-dispensing capabilities, especially its Opentrons Flex fully automatic pipetting workstation, which combines advanced robotics, open source software and artificial intelligence tools to provide scientists with efficient and accurate of microdispensing solutions. 1. Core parameters (1) Number of plates: 12 main deck positions, 4 dedicated plate positions for pipette tips and laboratory equipment (2) Pipetting range: 1-1000μL (3) Pipetting accuracy: accuracy at 1μL is 8%, and the accuracy is 5% at 1μL (4) Sample throughput: 96 samples (5) Instrument size: 87cm x 69cm x 84cm (width x depth x height) 2. Application scenario Opentrons The Flex fully automatic pipetting workstation can be configured according to different experimental needs and provides solutions for a variety of application scenarios, such as: (1) NGS library preparation: OPENTRONS FLEX NGS workstation is used for end-to-end NGS library preparation. (2) PCR setup and thermal cycling: OPENTRONS FLEX PCR workstation is used for PCR setup and thermal cycling. (3) Nucleic acid extraction: OPENTRONS FLEX nucleic acid extraction workstation performs nucleic acid extraction and purification based on the principle of magnetic bead extraction. (4) Protein purification: OPENTRONS FLEX protein purification workstation is used for small-scale protein purification. (5) Liquid dispensing work: OPENTRONS FLEX liquid dispensing workstation is used to aliquot samples into well plates.

The microdispensing workstation is a complex system that integrates multidisciplinary technologies such as mechanics, electronics, liquid handling, and automated control. Its various components cooperate with each other to achieve precise distribution and transfer of trace amounts of liquid, providing efficient and accurate experimental tools for scientific research.

The experienced service team and strong production support team provide customers with worry-free order services.