-

article · 2025Year42Moon26Day

Flex 工作站在蛋白质组学实验中的最佳实践是什么?

Read More -

article · 2025Year35Moon24Day

使用 Flex 工作站可以提高实验重复性吗?

Read More -

article · 2025Year47Moon23Day

Flex 工作站废料自动清理功能如何设置?

Read More

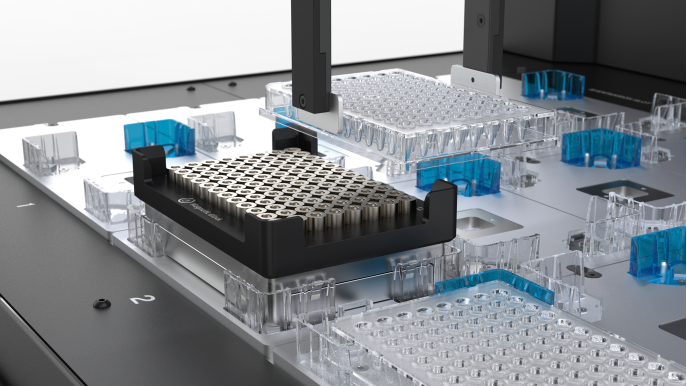

The automatic liquid dispensing workstation is an advanced laboratory equipment mainly used to automatically separate, distribute and transfer liquids. It integrates high-precision pipetting technology, automated control systems, and flexible operating interfaces, which can greatly improve experimental efficiency and accuracy and reduce human errors and contamination risks.

1. Main components The automatic liquid dispensing workstation usually consists of the following key parts: 1. Pipetting device: including a high-precision pipetting head or pipetting gun, which is used to accurately absorb and release liquids. These pipetting devices can often be adjusted to different volume ranges to meet the needs of different experiments. 2. Robotic arm or transmission system: Responsible for moving the pipetting device to a designated position to absorb, transfer and release liquid. The precision and stability of the robotic arm are crucial to the dispensing effect. 3. Control system: It is the core of the entire equipment, controlling the operation of the robotic arm and pipetting device through preset programs and parameters. Users can set parameters such as liquid dispensing volume, position, sequence, etc. through the operation interface, and the control system will automatically execute these instructions. 4. Container transport system: used to transport test tubes, deep-well microtiter plates and other containers to designated locations so that the pipetting device can transfer liquids. These systems typically include components such as conveyor belts and bottle conveyors. 5. Scanning and tracking systems: Containers such as test tubes and plates are often equipped with barcodes read by scanners to track and trace samples throughout the workflow.

2. Working Principle The working principle of the automatic dispensing workstation mainly includes the following steps: 1. Liquid aspiration: The pipetting device moves to the designated container through the mechanical arm, and accurately aspirates the liquid according to the preset parameters. 2. Liquid transfer: After absorbing the liquid, the robotic arm moves the pipetting device to the target container to release the liquid. This process can be repeated to complete the dispensing operation of multiple samples. 3. Sample tracking: Through the scanning and tracking system, the flow of samples can be recorded and monitored in real time to ensure the accuracy and traceability of the experiment.

3. How to use the automatic dispensing workstation 1. Preparation for equipment inspection: Confirm that the automatic dispensing workstation is in good condition, and check whether the pipette, robotic arm, sensor and other components are installed correctly and function normally. Cleaning and disinfection: Perform necessary cleaning and disinfection of pipettes, containers and other parts to avoid cross-contamination. Install consumables: According to the experimental needs, install the appropriate pipette head or suction tip, and check whether it is firmly fixed on the pipette. 2. Set parameters for startup and self-test: Start the automatic dispensing workstation and let it perform the self-test procedure to ensure that all functions are normal. Set dispensing parameters: Set dispensing volume, speed, position and other parameters through the operation interface or programming software. These parameters should be adjusted according to the specific requirements of the experiment. 3. Sample preparation and sample placement: Place the sample to be dispensed in the designated container or plate rack, and ensure that its position matches the settings of the dispenser workstation. Barcode scanning (if applicable): If the workstation has a barcode scanning capability, the barcode on the sample can be scanned to record sample information. 4. Start the dispensing program: start the dispensing program through the operation interface or programming software. The workstation will automatically perform liquid dispensing operations according to preset parameters and procedures. Monitoring process: During the dispensing process, pay attention to the working status of the workstation to ensure that no abnormality occurs. If a problem occurs, the program should be stopped in time and the cause should be checked. 5. Completion and cleaning. Dispensing is completed: When the dispensing procedure is completed, the workstation will automatically stop working. At this point you can check whether the dispensing results are as expected. Cleaning work: Remove the pipette head or suction head, and clean and disinfect pipettes, containers and other parts. Also clean the workstation work area and waste collection system. Shutdown and record: Shut down the automatic dispensing workstation and record experimental data and related information.

The automatic liquid dispensing workstation is one of the indispensable and important equipment in modern laboratories. With its characteristics of high precision, high efficiency, low pollution and flexibility, it plays an important role in scientific research exploration and technological innovation.

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인