-

article · 2025Year0Moon8Day

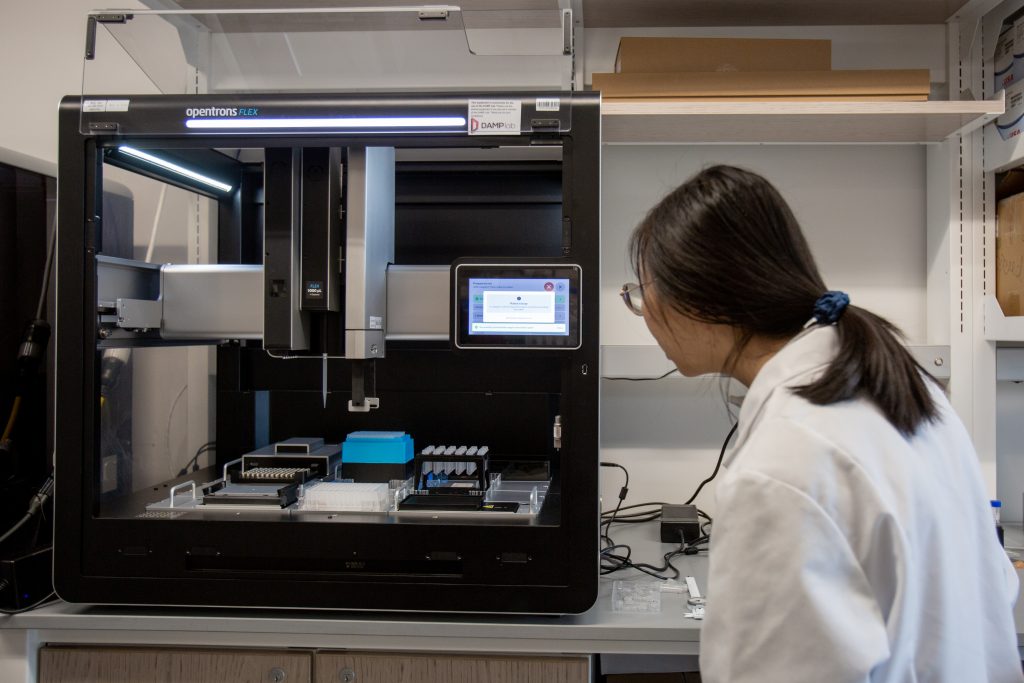

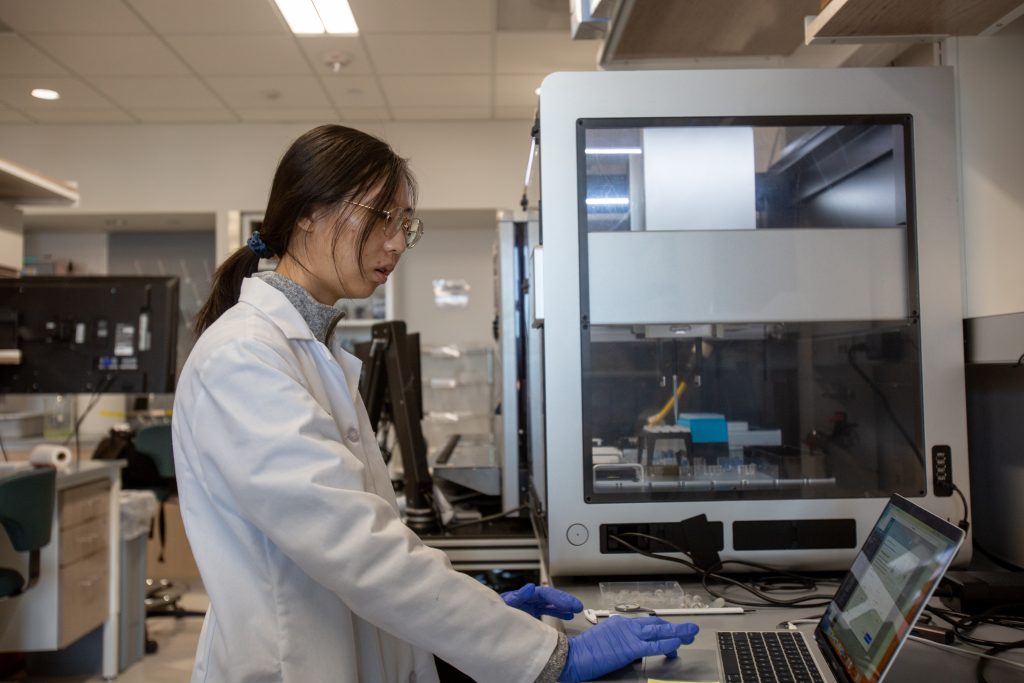

article · 2025Year0Moon8Day如何实现Flex平台对96/384孔板的高通量NGS任务?

Read More -

article · 2025Year55Moon8Day

article · 2025Year55Moon8DayFlex系统在样本清洗与纯化步骤中的优势有哪些?

Read More -

article · 2025Year12Moon7Day

article · 2025Year12Moon7DayFlex高通量NGS平台适合中小实验室吗?

Read More

The design of a fully automatic liquid handling system is a complex and highly integrated engineering feat, which deeply integrates cutting-edge knowledge in mechanics, electronics, automation control, liquid dynamics and other fields. The following is a carefully organized design framework, aiming to comprehensively and in-depth explain the main components, core working principles and key design considerations of the system.

1. Principle of fully automatic liquid handling system The working principle of the fully automatic liquid handling system is mainly based on the principles of automatic control and liquid dynamics. The system controls the coordinated movement of robotic arms, pumps, valves and other components through preset programs and parameters to achieve precise processing and delivery of liquids. During operation, the sensor monitors the status and parameters of the liquid in real time and feeds the data back to the control system for real-time adjustment and optimization.

2. Composition of a fully automatic liquid handling system 1. Robotic arm system: Responsible for liquid suction, transfer, distribution and other operations. It usually has multi-axis coordinated movement capabilities and can accurately position and operate. The design of the robotic arm needs to consider factors such as range of movement, accuracy, speed, and load capacity. 2. Liquid delivery system: including pumps, pipes, valves and other components, used for precise delivery and flow control of liquids. Depending on the experimental needs, different types of pumps (such as peristaltic pumps, syringe pumps, etc.) and pipeline materials can be selected. 3. Sensor system: used to monitor the position, flow rate, temperature and other parameters of the liquid in real time to ensure the accuracy and safety of the operation. Common sensors include liquid level sensors, flow sensors, temperature sensors, etc. 4. Control system: Based on advanced control algorithms and software, it realizes automatic control and optimization of the entire system. The control system needs to have high reliability, stability and ease of use, and be able to handle complex experimental processes and data. 5. Data analysis software: used for recording, analyzing and processing experimental data, providing visualization of experimental results and report generation. The software needs to have powerful data processing capabilities and a friendly user interface.

3. Design of fully automatic liquid handling system 1. Modular design: Modular design can be easily configured and expanded according to experimental needs, improving the flexibility and versatility of the system. Modules need to have good compatibility and interchangeability. 2. High-precision positioning: The robotic arm system needs to have high-precision positioning capabilities to ensure the accuracy and repeatability of liquid handling. Advanced positioning algorithms and sensor technologies can be used to improve positioning accuracy. 3. Intelligent control: The control system needs to have intelligent control functions that can automatically handle abnormal situations, optimize experimental procedures, and improve processing efficiency. Artificial intelligence algorithms and machine learning technology can be integrated to achieve higher levels of intelligent control. 4. Safety and reliability: System design must fully consider safety and reliability factors, including electrical safety, mechanical safety, liquid safety, etc. Corresponding safety protection devices and fault alarm systems must be equipped to ensure the safety and reliability of the experimental process. 5. Ease of maintenance: System design needs to consider factors of ease of maintenance, including ease of disassembly, cleaning, and replacement of parts. Detailed maintenance manuals and operating guides are available to facilitate daily maintenance and troubleshooting.

As an important part of modern laboratory automation, fully automatic liquid handling systems not only greatly improve the efficiency and accuracy of scientific research and production, but also create a safer, more convenient and efficient working environment for scientific researchers. With the continuous advancement and innovation of science and technology, fully automatic liquid handling systems will continue to integrate more advanced technologies, such as artificial intelligence, big data analysis, etc., to achieve more intelligent and personalized services.

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인