Flex应用专题 | 解锁蛋白质谱前处理自动化的无限潜能

Check the Details-

article · 2025Year3Moon9Day

清洗微孔板的具体步骤是什么

Read More -

article · 2025Year56Moon8Day

磁珠分选是什么

Read More -

Press release · 2025Year40Moon8Day

云端相约 | 邀您共同解锁蛋白质谱前处理自动化无限潜能

Read More

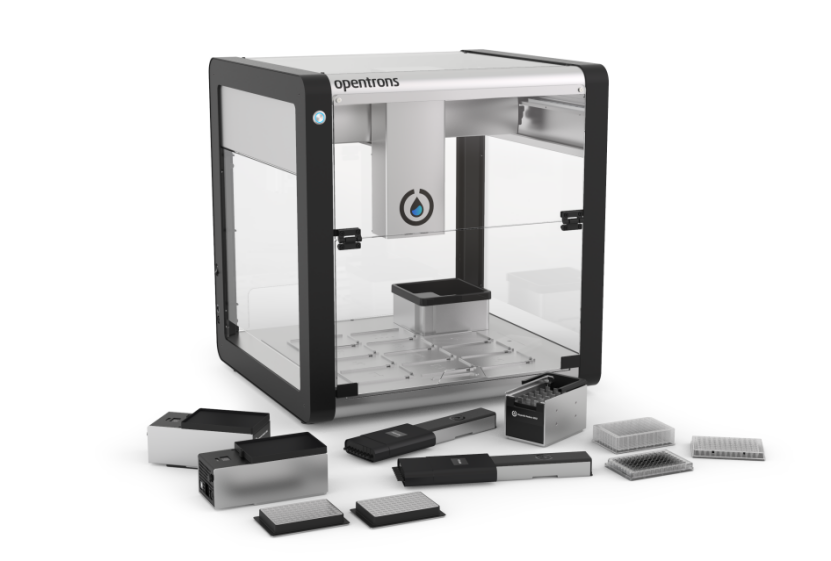

The fully automatic sample preprocessor is an efficient and accurate experimental equipment that is widely used in biomedicine, environmental monitoring, food safety and other fields. This instrument combines advanced automation technology and precise sample processing methods, which can quickly and accurately complete sample preprocessing work and provide reliable data support for subsequent experiments.

1. How to use the fully automatic sample preprocessor. The method of using the fully automatic sample preprocessor will vary according to different models and brands of equipment, but generally speaking, its usage process can be roughly summarized into the following steps:

1. Preparation stage (1) Check the instrument: Open the portable aluminum alloy box (if applicable), check whether the instrument is intact, whether all components are complete, and whether the power supply and vents are normal. Confirm that the instrument is in a safe and stable operating environment. (2) Turn on the power supply: Turn on the power supply of the instrument, and pay attention to the safe connection of the power cord to avoid clogging of the vent at the rear of the box. (3) Prepare samples: According to the experimental requirements, prepare samples to be processed to ensure that the samples meet the processing requirements of the instrument.

2. Setting parameters (1) Interface operation: Open the control interface of the instrument (which may be a touch screen, computer software, etc.) and enter the parameter setting interface. According to the experimental needs, set the corresponding parameters, such as temperature, time, rotation speed, liquid volume, etc. (2) Function module selection: Select the corresponding functional module according to your needs, such as drying, centrifugation, homogenization, mixing, etc. For each function module, specific parameters may need to be set separately.

3. Operation process (1) Sample loading: Load the prepared samples into the corresponding positions of the instrument as required, such as test tubes, sample tubes, etc. Pay attention to sample loading and positioning to ensure even sample handling. (2) Start the instrument: After setting all parameters, click "Start" or a similar start button to start the instrument for sample preprocessing. (3) Automatic processing: The instrument will automatically perform sample pre-processing operations according to the set parameters and procedures, such as drying, centrifugation, homogenization, mixing, etc. During the processing, users can monitor the processing progress and status in real time through the control interface.

4. Collection and processing results (1) Collect samples: After the processing is completed, collect the processed samples according to the experimental requirements. Be careful to avoid cross-contamination and loss of samples. (2) Data analysis: If necessary, use the instrument's own data processing function or external software to analyze and interpret the processing results.

5. Maintenance and maintenance (1) Clean the instrument: After use, clean all parts of the instrument in time to remove residues and stains. Pay special attention to cleaning and maintaining parts that are prone to clogging. (2) Care and maintenance: Carry out regular maintenance and care on the instrument, such as replacing worn parts, checking power lines, etc. Follow the instrument's instruction manual and maintenance manual for operation and maintenance. The above steps are only general operation procedures. Please refer to the operation manual and instructions of the instrument used for specific use. Different brands and models of fully automatic sample preprocessors may have different functions and operating details. Therefore, in actual use, the instructions provided by the instrument should be strictly followed.

2. The role of the fully automatic sample preprocessor 1. Improve processing efficiency: The fully automatic sample preprocessor can automatically complete multiple sample preprocessing steps, such as drying, centrifugation, homogenization, mixing, etc., greatly saving labor The operation time is improved and the efficiency of sample processing is improved. This is particularly important for laboratories that need to process a large number of samples, and can significantly shorten the experimental cycle and speed up research progress. 2. Reduce human errors: Traditional manual sample pre-processing methods are easily affected by human factors, such as unskilled operation, lack of concentration, etc., leading to inconsistency and errors in processing results. The fully automatic sample preprocessor reduces human intervention and the occurrence of human errors through precise automated control, and improves the accuracy and reliability of experimental results. 3. Protect the safety of operators: Some sample pre-processing steps may involve toxic, harmful or flammable and explosive chemicals, and manual operation involves certain safety risks. The fully automatic sample preprocessor adopts a closed or isolated design, which can protect operators from harmful substances to a certain extent and improve the safety of the experimental process. 4. Improve the repeatability of experiments: The fully automatic sample preprocessor can ensure the consistency of each processing process through standardized operating procedures and precise parameter control, thereby improving the repeatability of experimental results. This is of great significance for scientific research activities that require repeated experiments multiple times to verify the results. 5. Adapt to a variety of sample types: There are many types of samples involved in modern laboratories, including solids, liquids, gases, etc. Fully automatic sample preprocessors usually have a variety of functional modules and replaceable accessories, which can adapt to the preprocessing needs of different sample types and meet the diverse research needs of the laboratory. 6. Optimize the experimental process: The introduction of a fully automatic sample preprocessor can optimize the overall experimental process of the laboratory. Through automated processing, the circulation time and processing links of samples in the laboratory can be reduced, the risk of cross-contamination can be reduced, and the overall work efficiency and management level of the laboratory can be improved.

As an advanced experimental equipment, the fully automatic sample preprocessor not only improves laboratory work efficiency, but also brings more convenience and possibilities to scientific researchers. With the continuous advancement and innovation of technology, it is believed that fully automatic sample preprocessors will play an increasingly important role in future development, helping scientific research and experimental practice achieve more fruitful results.

The experienced service team and strong production support team provide customers with worry-free order services.