Flex应用专题 | 解锁蛋白质谱前处理自动化的无限潜能

Check the Details-

article · 2025Year3Moon9Day

清洗微孔板的具体步骤是什么

Read More -

article · 2025Year56Moon8Day

磁珠分选是什么

Read More -

Press release · 2025Year40Moon8Day

云端相约 | 邀您共同解锁蛋白质谱前处理自动化无限潜能

Read More

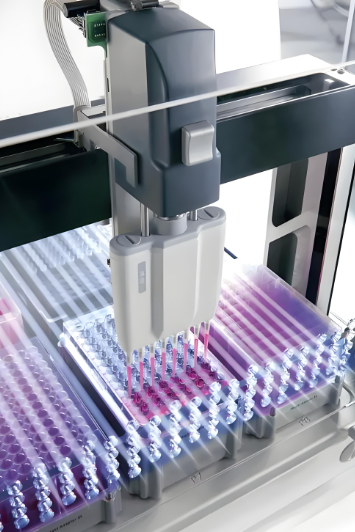

The 8-channel pipetting workstation is an advanced laboratory device used to process multiple sample liquids efficiently and accurately. Through its unique eight-channel design, it can perform multiple pipetting operations simultaneously, greatly improving the efficiency and accuracy of experiments.

1. The core components of the 8-channel pipetting workstation include:

1. Pipette: This is one of the core components of the workstation, responsible for the suction and distribution of liquids. The 8-channel design means that 8 samples can be processed per operation, which greatly saves time.

2. Control system: Control the operation of the pipette through a computer program to achieve high-precision and repeatable pipetting operations. Modern workstations often feature touch screens or software interfaces that allow users to easily set up and adjust parameters.

3. Sample stage: used to place the sample to be processed and the target container. The height and position of the sample stage can usually be adjusted as needed to accommodate different experimental needs.

4. Liquid handling system: including liquid storage tanks, pipelines and pumps, etc., used to provide the required liquid and ensure smooth flow of liquid throughout the system.

5. Waste liquid management system: Collect and process waste liquid generated during pipetting to ensure the cleanliness and safety of the experimental environment.

6. Automation module: Some advanced 8-channel pipetting workstations are equipped with automation modules, which can perform complex operations such as sample identification, automatic adding, and dilution.

7. Safety protection devices: such as splash baffles, alarm systems, etc., to ensure the safety of operators and the stability of the experimental process.

8. Power supply and sensor: ensure the normal operation of the equipment and monitor various operating parameters in real time.

9. In order to adapt to different experimental needs, 8-channel pipetting workstations are usually equipped with some accessories, such as pipetting heads, pipettes, filters, etc. These accessories further enhance the workstation's suitability and operational flexibility.

2. Things to note when choosing an 8-channel pipetting workstation

1. Demand matching

When selecting an 8-channel pipetting workstation, the appropriate model and configuration should be selected based on specific experimental needs. For example, laboratories that require high-throughput processing should choose workstations with a higher degree of automation.

2. Brand and quality

Choosing well-known brands and high-quality equipment can ensure long-term stable performance and good after-sales service. For example, opentrons Hechuang Bioengineering (Shenzhen) Co., Ltd.

3. Ease of operation

A modern 8-channel pipetting workstation should have a user-friendly interface and easy-to-maintain design to reduce operating complexity and maintenance costs.

4. Cost-effectiveness

When purchasing equipment, you should comprehensively consider the initial purchase cost and long-term use cost of the equipment, including maintenance, consumables, etc., and choose products with high cost performance.

As an efficient and accurate laboratory equipment, the 8-channel pipetting workstation is widely used in various scientific research and industrial fields. Through reasonable selection and use of this type of equipment, experimental efficiency and data accuracy can be significantly improved, providing strong support for scientific research and production.

If you have purchase needs or questions about other equipment, you can consult our platform’s online customer service or call the hotline. We look forward to hearing from you.

The experienced service team and strong production support team provide customers with worry-free order services.