Flex应用专题 | 解锁蛋白质谱前处理自动化的无限潜能

Check the Details-

article · 2025Year3Moon9Day

清洗微孔板的具体步骤是什么

Read More -

article · 2025Year56Moon8Day

磁珠分选是什么

Read More -

Press release · 2025Year40Moon8Day

云端相约 | 邀您共同解锁蛋白质谱前处理自动化无限潜能

Read More

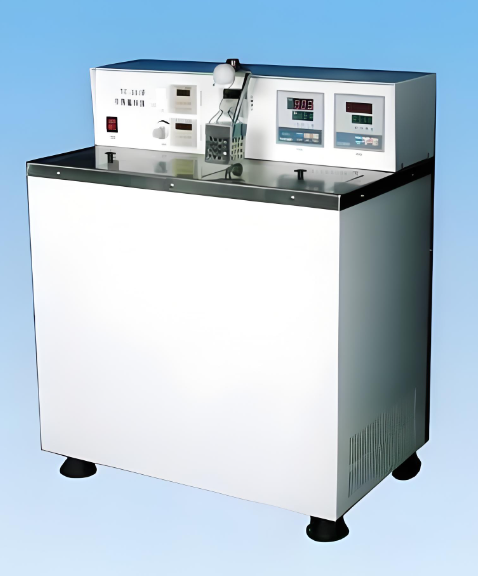

Thermal cycler, also known as dental thermal cycler or oral thermal cycler, is a device used to measure the temperature fatigue aging performance of materials, providing reliable and stable test conditions for material testing.

1. Basic functions and applications

1. Main functions: Thermal cycler is mainly used to simulate the performance of materials in a temperature changing environment, especially for the research of oral and dental materials. By periodically changing the temperature of the material, its stability and durability under different temperature conditions are evaluated.

2. Application fields: In addition to oral and dental materials, the hot and cold cycler can also be used in medical, chemical, pharmaceutical, universities and research institutes and other institutions for temperature fatigue aging performance testing of various materials.

2. Working principle and structure

1. Working principle: The hot and cold cycler automatically switches and places the test sample between high and low temperature water tanks through two or more constant temperature water tanks. After the sample is immersed in the low-temperature tank for a certain period of time, it is lifted up by a robotic arm or other device and placed into the high-temperature tank. After staying in the high-temperature tank for a certain period of time, the sample is lifted back to the low-temperature tank. This process is repeated to simulate the temperature change environment of the material in actual use.

2. Structural features: The equipment usually includes a large constant-temperature water tank, a mobile basket (for placing samples), a microcomputer controller, and related mechanical transmission devices. The controller can freely set parameters such as tank temperature, speed of soaking and exposing samples, basket residence time in each tank, and number of cycles.

3. Technical parameters and performance

1. Temperature range: The temperature control range of the low-temperature bath of the thermal cycler can usually reach 0~100℃, and the temperature control range of the constant temperature bath can reach room temperature (RT) to 100℃. The temperature accuracy and uniformity are also high, with general accuracy up to ±0.1°C and uniformity up to ±0.3°C.

2. Conversion speed and residence time: The adjustable range of the conversion speed between tanks is usually 2 ~ 20rpm (or higher), and the adjustable range of the residence time in the tank ranges from a few seconds to a few minutes.

3. Cycle times: The equipment can set a wide range of cycle times, generally ranging from 1 to millions of times.

4. Controller and display: Modern thermal cyclers usually use LED or LCD liquid crystal display controllers, which can visually display parameters such as temperature, conversion speed, residence time, number of cycles, etc., and have automatic counting functions.

4. Use and maintenance

1. Precautions for use: When using the hot and cold cycler, care should be taken to avoid opening the door at will while the equipment is running, so as not to affect the test results and cause safety hazards. At the same time, the operating status of the equipment should be checked regularly, and any abnormalities should be dealt with promptly.

2. Maintenance: Regular maintenance of the hot and cold cycler is the key to ensuring its long-term stable operation. This includes cleaning equipment, inspecting mechanical transmissions, replacing aging parts, etc. In addition, equipment should be regularly calibrated and verified to ensure the accuracy and reliability of test results.

Thermal cycler is a powerful and widely used material testing equipment. By simulating the performance of materials in a temperature changing environment, it provides strong support for material research and product development. The operation of the thermal cycler is like building a bridge for the world of materials, connecting the ideal environment of the laboratory with the vast world of practical applications, making it possible to explore the limits of material performance and improve product quality.

The experienced service team and strong production support team provide customers with worry-free order services.