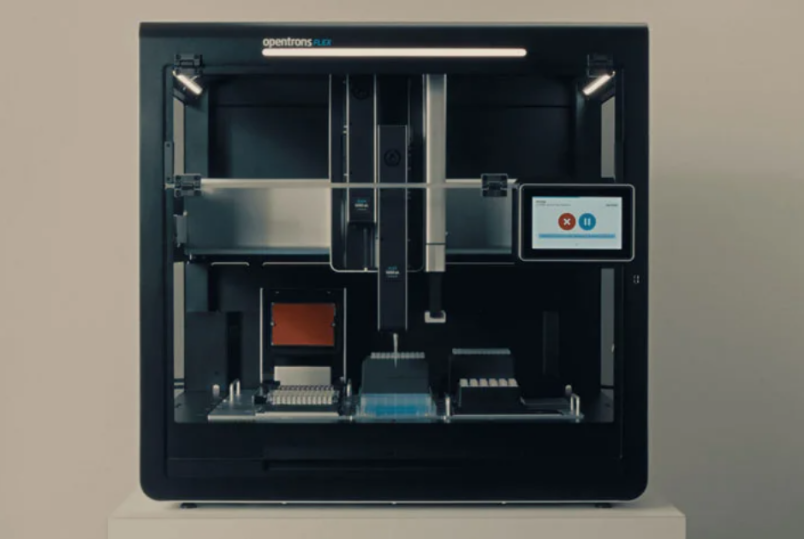

Flex应用专题 | 解锁蛋白质谱前处理自动化的无限潜能

Check the Details-

article · 2025Year3Moon9Day

清洗微孔板的具体步骤是什么

Read More -

article · 2025Year56Moon8Day

磁珠分选是什么

Read More -

Press release · 2025Year40Moon8Day

云端相约 | 邀您共同解锁蛋白质谱前处理自动化无限潜能

Read More

The fully automatic liquid workstation is a system that integrates a variety of automated equipment and technologies. It is mainly used for liquid processing and analysis in biology, chemistry, medicine and other fields. Its equipment usually includes the following core parts:

1. Liquid processing platform of fully automatic liquid workstation

1. Automatic weighing instrument: used for precise quantitative packaging of liquid samples to ensure the accuracy of the liquid amount during the experiment.

2. Sample processor: completes the precise addition of samples, supports the processing of a variety of containers and samples, and improves experimental efficiency.

3. Reactor: As the basic equipment to complete experimental reactions, it supports the conduct of various chemical reactions.

4. Liquid distribution device: including suction heads, needles, air pumps, solenoid valves and other components, used to achieve precise distribution and mixing of liquids.

5. Transport arm: Responsible for moving the liquid distribution device to a designated position to absorb, transfer and release liquid.

2. Analysis platform of fully automatic liquid workstation

1. High performance liquid chromatography: used for efficient and accurate separation and analysis of samples, and is widely used in pharmaceutical analysis, environmental monitoring and other fields.

2. Gas chromatograph: The volatile components in the sample are analyzed through gas chromatography, which has the characteristics of high sensitivity and high resolution.

3. Mass spectrometer: used in combination with gas chromatography to conduct qualitative and quantitative analysis of compounds in samples. It is an important analytical tool in the fields of biology, chemistry and other fields.

3. Data analysis platform of fully automatic liquid workstation

1. Data acquisition system: Responsible for real-time collection of various data generated during the experiment, including liquid volume, reaction temperature, pressure and other parameters.

2. Data processing system: Process and analyze the collected data, extract useful information, and support functions such as data visualization and report generation.

3. Laboratory Information Management System (LIMS): Connected to the data processing system, it is used to manage experimental data, experimental processes, experimental personnel and other information to improve laboratory management efficiency.

4. Other ancillary equipment and software systems of the fully automatic liquid workstation

1. Liquid cabinet: used to store various liquid samples and reagents to maintain their stability and safety.

2. Storage equipment: such as refrigerators, freeze dryers, etc., used to store and process samples under specific conditions.

3. Laboratory furniture: such as experimental benches, fume hoods, etc., provide the necessary working environment and safety guarantee for experiments.

4. Software system: including experimental design system, data management system, etc., used to optimize experimental processes, manage experimental data, and improve experimental efficiency.

The fully automatic liquid workstation is a complex system that integrates a variety of automated equipment and technologies. Its equipment covers many aspects such as liquid processing, analysis, and data processing. It provides a strong foundation for experiments and research in the fields of biology, chemistry, medicine, etc. Strong support.

The company focuses on providing a full range of core components of fully automatic liquid workstations, aiming to create efficient and accurate automated experimental solutions for customers. To learn more about the detailed specifications and performance advantages of each device, please visit the Opentrons official platform product list, or contact our website staff directly for one-on-one professional consultation and answers.

The experienced service team and strong production support team provide customers with worry-free order services.