Flex应用专题 | 解锁蛋白质谱前处理自动化的无限潜能

Check the Details-

article · 2025Year3Moon9Day

清洗微孔板的具体步骤是什么

Read More -

article · 2025Year56Moon8Day

磁珠分选是什么

Read More -

Press release · 2025Year40Moon8Day

云端相约 | 邀您共同解锁蛋白质谱前处理自动化无限潜能

Read More

Molecular analysis requires precise pipetting of reagents and samples with varying properties—including viscous ones that can clog the tip, uneven distribution, and complex reproducibility. The Opentrons OT-2 is an automated liquid handling robot capable of removing these difficult liquids. Default parameters in the properties of the Opentron protocol Python API are optimized for efficient and accurate processing of water reagents. Commonly used reagents vary in properties such as viscosity, evaporation rate, and surface tension. These inherent liquid properties require changes in the default protocol parameters to meet optimal processing for a given workflow. This application note focuses on best practices for automated handling of viscous liquids using the Center OT-2 based on testing using computer vision based methods and gravimetric methods.

Viscous liquids Viscous liquids have different rheological properties, such as different densities (e.g. low in oil but high in glycerin), different surface tensions (e.g. low in soap but high in mercury), viscosity, etc. We classify viscous liquids, such as honey, glycerin, and oils, which may require specialized pipetting parameters.

Table 1: Characterization of viscous liquids based on their molecular structure, vapor pressure and surface tension.

Glycosylated Liquids Glycosylated liquids are composed of sugars and have high adhesion to the pipette tip wall and relatively high cohesion compared to other viscous liquid categories mentioned in Table 1. The viscosity of these liquids varies with the degree of dilution. Since these liquids stick to the tip, it slows removal of the tip after aspiration and dispensing from the liquid, helping to avoid bubbles, droplet formation, and clean aspiration and dispensing.

Volatile viscous liquids Volatile viscous liquids are a mixture of glycerin/polyethylene glycol and volatile solvents such as ethanol or isopropyl alcohol. The addition of glycerol/polyethylene glycol increases viscosity, while volatile solvents increase vapor pressure. Therefore, when pipetting such liquids, the user can use the default aspiration flow rate used for water. However, the dispensing flow needs to be reduced to offset dripping problems due to higher vapor pressure, and adding an air gap after aspiration is necessary to ensure accurate pipetting.

Viscous surfactant liquid Viscous surfactant liquid is a mixture of surfactants and viscous glycosylated liquids. The most popular viscous surfactants are Tween® 20 and Triton® X-100, with viscosities up to 400 milliPascal seconds (mPa). These liquids showed higher adhesion to the pipette tip, but lower adhesion force. Viscous surfactants must be inhaled at a slower suction flow and withdrawn at a minimum withdrawal speed. The dispensing flow rate needs to be reduced to give the liquid enough time to leave the walls of the pipette tip.

One way to compensate for slow traffic is to use longer delays with two-step distribution. For example, if you are dispensing 200 uL of viscous surfactant with a GEN2 P300 single-channel pipette, divide the dispensing step into two parts: first dispense ½ to ¾, increasing the pause in liquid flow toward the tip orifice; then, dispense slower than ½ of 50 uL, making sure to add an extra blow out step and a slower touching tip step. As an additional step for rapid dispensing, a touch-dispensing strategy can be implemented when the pipette contacts the well wall.

Grease exhibits similar properties to viscous surfactants and can be treated using the methods described above. The oil takes longer to completely slide off the wall, which means the pipette takes longer. Slower extraction helps reduce the loss of oil sticking to the outside wall of the pipette tip, but because the oil's adhesion to the tip is higher than the oil's cohesion, clean dispensing of the oil requires longer liquid settling time, resulting in delays. Based on estimates of dead volume loss of the oil reagent, longer delays can be implemented after the aspiration and dispensing steps. Touch Tip Dispensing and Touch Tip functionality are also a great way to reduce losses by adding faster dispensing speeds. Slower aspiration and dispensing, slower tip withdrawal of liquid, and slower blowout flow rate are key parameters that influence the viscous liquid handling experience and clean liquid pipetting.

Method Based on the rheological properties of the liquid, the specifications of the pipettes and the contours of the laboratory vessels used, we developed an optimized strategy for the handling of viscous liquids using OT-2. This study was limited to the viscous liquid handling capabilities of the GEN2 single-channel pipette. The liquid handling functions implemented are suction and suction and distribution; when complex liquids are mixed or formed, and different workflows may require different parameters, the parameters may not work.

Materials were prepared with varying dilutions of glycerol 99% (Sigma-Aldrich, G5516) diluted with molecular grade water (Invitrogen, Carno. 10977023). 1 Glycerol is a viscous liquid with a viscosity ranging from 1 mPa to 1400 mPa, varying Depends on dilution. Therefore, we consider glycerol to be a representative liquid of the viscosity class, and viscosity can be understood qualitatively and compared with liquids of similar viscosity. Since the viscosity of glycerol increases exponentially, we selected 10%, 90%, and 99% glycerol for parameter development. All concentrations are in 15 ml Falcon tubes, 10 ml of glycerol and water in two ratios: glycerol 90%, glycerol 10%. The No. 15 tube rack adapter is placed on the No. 7 rack. Tested using Opentrons GEN2 single channel V2.2 pipettes: P20, P300 and P1000. We also used the P20 tip and the P300 filter tip and the P1000 filter tip. Features integrated thermometer and hygrometer.

Weight Test Method Weight testing was performed on a custom drill rig with a weighing scale attached to the OT-2. The scale was placed on a separate bench to isolate vibrations generated by the OT-2. Glycerol concentrations of 10%, 90% and 99% molecular grade water were tested on a gravimetric test bench. . 3 volumes of 1uL, 10µL and 20µL tested with P20 GEN2 pipettes, 4 times per volume. P300 GEN2 pipettes 20µL, 150µL and 300µL, 10 strokes per volume. P1000 GEN2 Pipette 100µL, 500µL and 1000µL. Repeat 10 times per volume. The ambient temperature of the test is 23°C~32°C, and the relative humidity is 35%~45%.

The programming parameters of OT-2 are appendix table A1, A1, A2 and A3 in Python protocol PAPI2.9 to perform aspiration, dispensing and insufflation at the required flow rate. Test water using default parameters of intake, distribution and blowout.

Optimization results and discussion The three concentrations of glycerin expected to be selected, 99%, 90% and 10%, respectively, are based on the dynamic viscosity of glycerol as a representative of the viscous liquid class. The dynamic viscosity of glycerol is 1.3mPa, 10% is 168 mPa, glycerol is 90%, and the concentration of 99% glycerol is 893mPa.

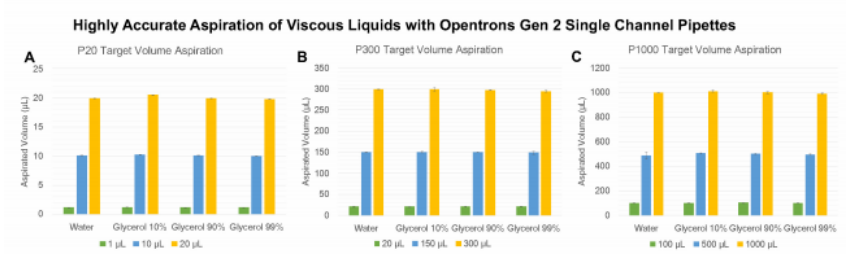

Figure 1 shows that optimized parameters for viscous liquids show greater relevance for water treatment:

The results in Figure 1 show viscous liquids using GEN2 P20, P300, and P1000 pipettes and filters. The key to accurate aspiration is to have a slow flow rate, adequate settling time, and a slow extraction rate. Highly viscous liquids require lower aspiration times, even if higher flow rates are used. The compensation, however, is that inaccurate volumes can be aspirated due to gravity and adhesion at the tip.

These results are achieved by aspirating slowly and allowing sufficient settling time for the aspirated liquid to overcome these adhesion forces. Therefore, the lag time between the liquid suction movement of the plunger and the time it takes for the liquid to be sucked in can be overcome by the settling time. Although the liquid has a high affinity to the tip, extraction is faster. The results are information about droplets and liquid spillage around the tip. The optimized parameters achieved slower tip extraction speeds, resulting in clean tip withdrawal and high reproducibility of aspirated volumes, as shown in Table 2.

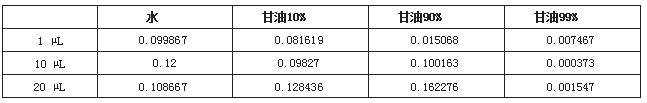

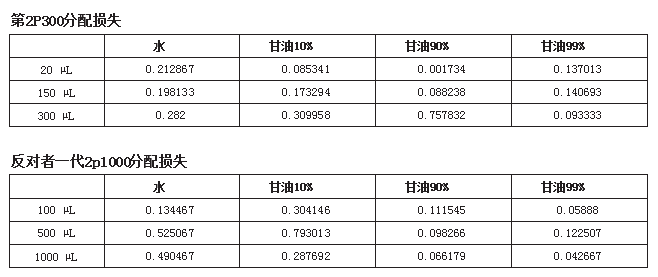

Table 2: Minimum losses for dispensing viscous liquids. The optimized parameters allow < 0.9% loss for the GEN2 P20 single-channel pipette and < 0.2% loss for the GEN2 P300 and GEN2 P1000 single-channel pipettes after dispensing.

2P20 Distribution Loss

Completely distributes the liquid within the tip by synchronizing the flow of liquid within a narrow area of the tip to remove excess liquid. Additionally, slowing down the extraction speed of the tip can also help avoid splashing and getting stuck. If the liquid is not mixed, the viscosity does not change and the parameters remain unchanged after pumping and dispensing. As shown in Table 2, the entire optimized dispensing process significantly reduced pipetting losses and provided the expected target volume for the reaction, thereby improving accuracy.

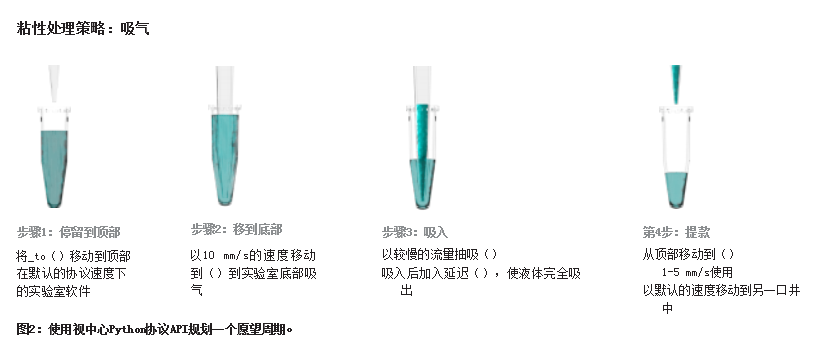

Conclusion The viscosity test results verified that the OT-2 with the GEN2 single-channel pipette can handle liquids of different viscosities with an accuracy comparable to the water treatment capabilities of the OT-2 with high accuracy. Optimized recommended parameters and guidelines improve the liquid handling performance of OT-2 and help ensure successful protocol runs. Figures 2 and 3 summarize the implementation of viscous classes and lower flow rates and critical settling times to allow viscous liquids to settle; therefore , sequential steps such as slow blowout help to reduce viscous liquid loss, enabling efficient use of reagents and improving the accuracy of results.

If the air volume is too low or too high for liquid dispensing, an air gap can be implemented before aspirating the viscous liquid with a slower dispensing rate, rather than a slower injection, to achieve the desired air volume and reduce the viscosity to Liquid is pushed out of the tip, but the trade-off is that less liquid can be aspirated than the pipette's maximum limit. This may not be the best situation for use with the GEN2 P20 single channel pipette. Finally, slower extraction speeds after the aspiration and dispensing steps are highly recommended to prevent droplets from sticking to the tip and reagents from spilling into the labware.

In summary, the OT-2 and GEN2 single-channel pipettes and filter tips can optimally handle viscous liquids and improve the accuracy of the protocol.

Viscous Liquid Handling Parameters A key parameter in handling viscous liquids is the distribution flow rate. If you are developing a protocol for a completely new viscous liquid, the first step is to aspirate slowly and withdraw slowly so that you have a clean aspiration cycle. Slower flows and velocities result in viscous liquid handling. Additionally, you can start dispensing at a rate where you can observe the liquid meniscus uninterrupted. Maintaining a stable meniscus results in clean distribution and blowouts. Figure A1 illustrates the problem associated with higher flow rates: dead volume can be created if excess liquid within the explosion is not removed. Higher flow rates force liquid out of the center, and excess liquid sticks to the walls of the tip. If the pipette's blowout capacity is lower than the excess volume inside the tip, dead volume results. Therefore, maintaining a low flow rate is necessary.

Original address:Automation of viscous liquid handling using the Center OT-2

The experienced service team and strong production support team provide customers with worry-free order services.